ZP Mehrschicht-Tablettenpresse

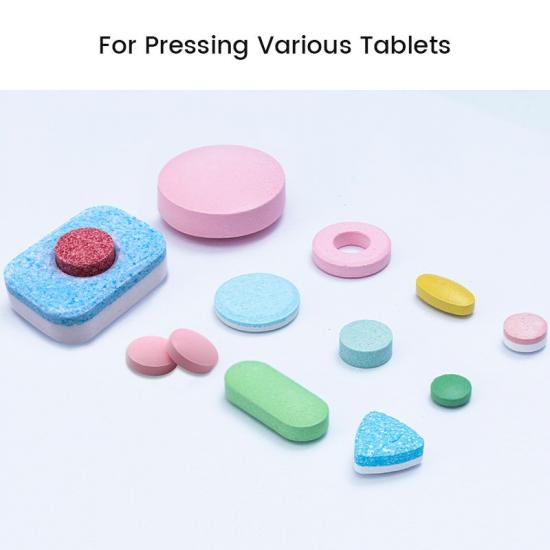

Can he achieve three colors or all three layers evenly distributed on one tablet? Yes, the three-color tablet rotary tablet press machine can evenly mix and compress three-color powders into one tablet, so that three colors or three layers can be evenly distributed on one tablet. This is usually done by mixing powders of different colors together in a certain proportion, and rotating and extruding in a rotary tablet press to form uniform three-color tablets. Exactly how this is achieved may vary from device to device, but rotary tablet presses can often achieve this.

Do you need a forced feeder? In the manufacturing process of three-color tablets, if it is necessary to precisely control the proportion and amount of each drug powder, it can be used with a forced feeder. A forced feeder ensures that each powder is fed into the rotary tablet press in the exact proportions required to achieve the desired color and dose distribution. However, if the three-color film produced does not require very precise ratio and quantity control, it does not necessarily need to be equipped with a forced feeder.

What is the output per hour? The production efficiency of a three-color tablet rotary tablet press depends on many factors, such as the specification of the equipment, the skill level of the operator, the nature of the raw material, and so on. Therefore, hourly output may vary by device model. Generally speaking, the production efficiency of a rotary tablet press can range from thousands to tens of thousands of tablets per hour, while the manufacturing speed of three-color tablets is limited by the drug formulation, tableting speed and equipment capabilities. Therefore, the specific hourly output needs to be evaluated and determined according to the actual situation.

*** Technical parameter

| Model |

ZP-25/55D Multi Layer Model |

| Max. Production Capacity |

115,000 pcs/h |

| Max. Pressure |

100KN |

| Max. Dia. of Tablet |

25mm |

| Max. Thickness of Tablet |

12mm |

IPv6-Netzwerk unterstützt

IPv6-Netzwerk unterstützt