Apfelessigkapseln sind weit verbreitet, aber wie viele Hersteller können die gleichbleibende Qualität bei der Massenproduktion wirklich gewährleisten?

Apfelessig hat sich dank angeblicher appetitzügelnder, verdauungsfördernder und blutzuckerregulierender Wirkung zu einem beliebten Nahrungsergänzungsmittel entwickelt. Doch Vorsicht: Apfelessig ist nicht gleich Apfelessig.

Die Inhaltsstoffe, das Verhalten des Pulvers in der Fabrik und die Kapselfüllmaschinen entscheiden darüber, ob ein Produkt vertrauenswürdig ist. Stellen Sie sich zwei Marken nebeneinander im Regal vor: Die eine liefert konstant die versprochene Dosis mit minimalem Geruch und lässt sich leicht schlucken; die andere schwankt von Charge zu Charge, verklumpt manchmal und kann einen bitteren Nachgeschmack hinterlassen. Welcher würden Sie vertrauen? Dieser Abschnitt befasst sich daher mit der Herstellung von Apfelessigkapseln, zeigt die häufigsten Herausforderungen auf und gibt Tipps zur Qualitätskontrolle.

Wichtigste Erkenntnisse

● [endif] Grundlagen und Vorteile von Apfelessig

● Was „gute Qualität“ aus Verbraucher- und Herstellersicht bedeutet

● Gemeinsame Produktionsherausforderungen

● Praktische Lösungen auf Maschinen- und Prozessebene

● Wie Rich Packing eine zuverlässige Produktion sicherstellt

Apfelessig wird durch die Vergärung von Apfelsaft zu Alkohol und anschließend zu Essigsäure hergestellt. Haushaltsüblicher Apfelessig enthält üblicherweise 4–7 % Essigsäure und manchmal eine Mischung aus Enzymen und Pektin-Nebenprodukten.

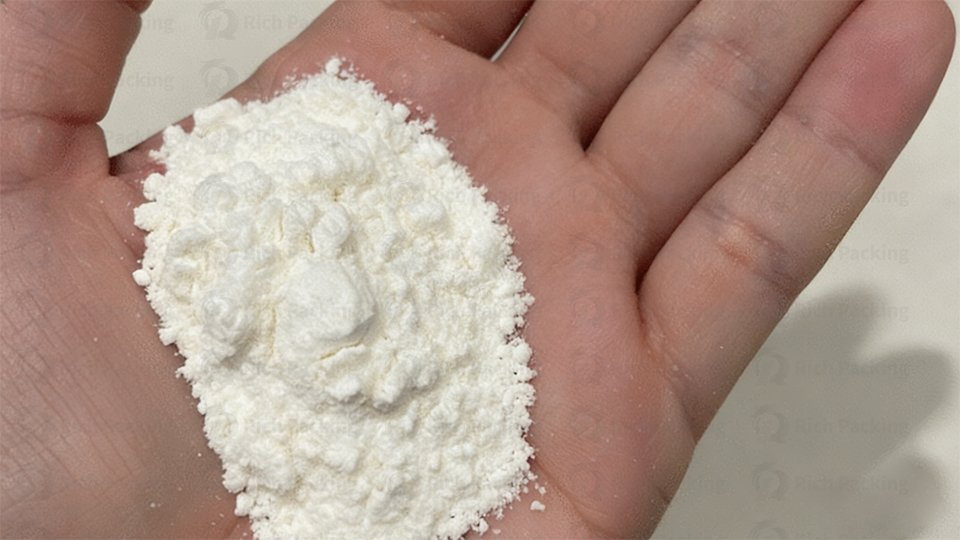

In Nahrungsergänzungsmitteln wird Apfelessig üblicherweise zu sprühgetrocknetem Pulver oder konzentriertem Extrakt verarbeitet, um das Abfüllen in Kapseln oder Tabletten zu erleichtern. Die Pulverform ermöglicht eine präzise Dosierung und eine stabile Haltbarkeit, was für Hersteller von Nahrungsergänzungsmitteln unerlässlich ist.

Wissenschaftliche Studien legen nahe, dass Apfelessig die Stoffwechselgesundheit in kleinem, aber messbarem Maße unterstützen kann:

Gewichtsmanagement: Mehrere randomisierte Studien ergaben, dass täglich Apfelessig zur Gewichtsabnahme Die Einnahme führte zu statistisch signifikanten Reduktionen des Körpergewichts und des BMI bei übergewichtigen Erwachsenen oder Erwachsenen mit Typ-2-Diabetes.

Blutzuckerkontrolle nach dem Essen: Forschungsergebnisse deuten darauf hin, dass die Einnahme von Apfelessig um die Mahlzeiten herum den Blutzuckeranstieg nach dem Essen abmildern kann, indem die Magenentleerung und die Kohlenhydratverdauung verlangsamt werden, was zu einer stabileren Glukosefreisetzung führt.

Lipide: Nach regelmäßigem Apfelessigkonsum zeigten sich geringfügige Verbesserungen bei den Nüchternblutfett- und Cholesterinwerten, allerdings ist die Beweislage hier weniger aussagekräftig als bei den Ergebnissen zu Glukose und Gewicht.

◆ [endif] Wichtiger Hinweis: Apfelessig ist ein unterstützendes Mittel zur Ernährung, kein Medikament. Die positiven Wirkungen sind gering und entwickeln sich mit der Zeit. Am besten kombiniert man ihn mit einer gesunden Ernährung. Übermäßiger, langfristiger Konsum kann Nebenwirkungen wie Kaliummangel oder Zahnschmelzerosion verursachen.

Im Handel wird ACV wie folgt bezeichnet:

Flüssig: Starker Geschmack, Gefahr von Halsreizungen, muss gekühlt werden.

Pulver-/Stickpackungen: Tragbar, mischbar, aber feuchtigkeitsempfindlich.

Gummibärchen: Apfelessig-Gummibärchen Sie schmecken gut, sind aber schwieriger genau zu dosieren.

Kapseln/Tabletten: Wird üblicherweise als Pulver mit genauer Dosierung gehandhabt, ist stabil und leicht zu transportieren.

Kapseln überdecken zwar den herben Geschmack von Apfelessig, doch entscheidend ist vor allem die gleichbleibende Dosierung pro Portion sowie die vereinfachte Lagerung und der Transport. Für Hersteller ermöglichen Kapseln eine präzise Gewichtskontrolle und eine leichtere Rückverfolgbarkeit gemäß den gesetzlichen Bestimmungen – vorausgesetzt, Ihre Produktionslinie für Apfelessigkapseln ist für das feine, feuchtigkeitsempfindliche Pulver geeignet.

Bevor wir uns mit den technischen Details befassen, ist es wichtig zu verstehen, dass „Qualität“ zwei Seiten hat: die Wahrnehmung des Endverbrauchers und die internen Qualitätskontrollen des Herstellers. Beide Perspektiven sind entscheidend für die Herstellung eines vertrauenswürdigen Apfelessigpräparats.

Aus Verbrauchersicht sollte eine hochwertige Apfelessigkapsel folgende Eigenschaften aufweisen:

● Leicht zu schlucken: Die Kapseln sollten glatt sein und eine angemessene Größe haben, damit sie ohne Beschwerden oder Erstickungsgefahr eingenommen werden können.

● Leicht verdaulich: Durch die sorgfältige Zusammensetzung wird sichergestellt, dass das Apfelessigpulver den Magen und den Verdauungstrakt nicht reizt, sodass der tägliche Verzehr sicher und gut verträglich ist.

● Vorhersehbare Effekte erzielen: Die Verbraucher erwarten eine gleichbleibende Leistung, das heißt, jede Dosis unterstützt zuverlässig die Verdauung, die Appetitregulierung oder die Blutzuckerstabilisierung.

● Vertrauenswürdige Signale: Analysenzertifikate (COA), klare Dosierungsanweisungen und Chargencodes geben den Verbrauchern Sicherheit.

Hersteller von Apfelessigkapseln definieren die Qualität von Apfelessigkapseln anhand messbarer Aspekte:

Dosierungsgenauigkeit: Die Pulverfüllgewichte werden überwacht, um sicherzustellen, dass jede Kapsel die vorgesehene Menge enthält, typischerweise innerhalb enger Toleranzen (üblicherweise etwa ±2-3%), die durch Inline-Gewichtskontrollen überprüft werden.

Physische Unversehrtheit: Die ACV-Kapseln werden mittels automatisierter Bildverarbeitungssysteme oder manueller Inspektion auf Risse, Spalten oder Undichtigkeiten geprüft, um die Anzahl fehlerhafter Einheiten zu minimieren. Pro Charge liegt der Anteil gerissener oder undichter Kapseln bei unter 0,5 %.

Stabilität Der Wirkstoffgehalt bleibt während der gesamten Haltbarkeitsdauer innerhalb der Spezifikationen. Hochwertige Formulierungen behalten unter Standardlagerbedingungen (20–25 °C, <60 % relative Luftfeuchtigkeit) über 24 Monate ≥95 % ihres Essigsäuregehalts.

Prozesseffizienz: ACV-Hersteller überwachen die Erstausbeute, die Ausschussrate und die Chargenkonsistenz, um die Stabilität der Produktionslinie zu bewerten. In gut kontrollierten Anlagen Kapselbefüllung Die Ausbeute im ersten Durchgang liegt typischerweise über 98 %, die Ausschussraten bleiben unter 2 % und die kritischen Prozessparameter werden innerhalb einer Abweichung von ±1,5 % gehalten.

Auf Grundlage dieser Qualitätskennzahlen sehen sich selbst erfahrene Hersteller immer wieder mit Herausforderungen bei der Herstellung von ACV-Kapseln konfrontiert:

■ Ungenauigkeit bei der Pulverfüllung

■ Pulverbrückenbildung und Leckage

■ Kapselbruch und Verstopfungen

■ Hohe Reinigungsausfallzeiten

■ Umgang mit Säure

Jedes der oben genannten Probleme kann den Ertrag mehr oder weniger stark mindern und das Vertrauen der Verbraucher schleichend untergraben. Daher ist es für Hersteller von Apfelessigpräparaten von entscheidender Bedeutung, die Ursachen dieser Probleme zu verstehen.

Bevor wir die eigentlichen Ursachen dieser Probleme untersuchen, ist es wichtig, den grundlegenden Herstellungsprozess von Apfelessigkapseln zu verstehen. Dies liefert den Kontext, wo typischerweise Probleme auftreten und wie sich jeder Schritt auf die Qualität des Endprodukts auswirkt. Apfelessigkapseln werden in einem strukturierten, mehrstufigen Verfahren hergestellt, das Apfelessig in ein stabiles, präzise dosiertes Kapselprodukt umwandelt.

Die Herstellung hochwertiger Apfelessigkapseln beginnt mit der Auswahl der richtigen Zutaten und deren sachgemäßer Verarbeitung. Hier eine detaillierte Aufschlüsselung:

Apfelessigpulver oder -konzentrat: Üblicherweise wird es sprühgetrocknet, um eine gleichbleibende Konsistenz zu gewährleisten. Es muss frei rieselfähig sein, damit jede Kapsel die korrekte Dosis erhält.

Fließ- und Trennmittel: Inhaltsstoffe wie Kieselsäure oder Magnesiumstearat helfen, Klumpenbildung zu verhindern und sorgen dafür, dass das Pulver reibungslos durch die Maschine fließt.

Kapselhüllen: Es wird Gelatine oder HPMC verwendet, wobei Glycerin oder Wasser hinzugefügt werden, um der Hülle Flexibilität zu verleihen und ein zuverlässiges Auflösen zu gewährleisten.

Optionale Mischungen: Manche Rezepturen enthalten Pflanzenextrakte wie Zimt oder Kurkuma oder Vitamine für zusätzliche Vorteile.

Feuchtigkeitsregulierung: Apfelessig und viele Hilfsstoffe reagieren empfindlich auf Feuchtigkeit, daher werden alle Materialien trocken und klimatisiert gelagert. Dies gewährleistet, dass das Pulver für die Produktion rieselfähig und von gleichbleibender Qualität bleibt.

✧ [endif] Ein kleiner Tipp für die Hersteller: Durch die Handhabung von Pulvern in einer kontrollierten Umgebung von Anfang an kann ein späteres Verklumpen verhindert und die Ausfallzeiten beim Befüllen der Kapseln reduziert werden.

Um ACV-Kapseln effizient und gleichmäßig herzustellen, integriert eine komplette Produktionslinie mehrere spezialisierte Maschinen, von denen jede einen kritischen Schritt vom Mischen und Abfüllen bis zum Zählen und Verpacken übernimmt.

Eine Standard-Hartkapsel-Produktlinie umfasst:

● Niedrigschermischer

● Futterstellen

● Automatische Kapselfüllmaschinen

● Fertige Kapselpoliermaschinen

● Zählmaschinen

● Kontrollwaage

● Trockenmittel-Einfüllmaschine

● Etikettiermaschine

● Verschließmaschine

● Induktionssiegelgerät

● Kartoniermaschine

Sobald die Zutaten und die Ausrüstung bereit sind, folgt die Herstellung der ACV-Kapseln einer systematischen Abfolge von Schritten, um eine genaue Dosierung, saubere Handhabung und zuverlässige Verpackung zu gewährleisten.

● Mischen und Pflegen

● Fütterung

● Kapselfüllung

● Polieren

● Zählen und Abfüllen von Verpackungen

● Qualitätsprüfung

● Beschriftung

● Kappen

● Folieninduktion

● Kartonierung

Das Pulververhalten und die Maschinenkonstruktion entscheiden darüber, ob jeder Arbeitsschritt reibungslos abläuft oder häufige Unterbrechungen auslöst.

Um zu verstehen, warum diese Qualitätsprobleme weiterhin bestehen, ist es wichtig zu sehen, wie Apfelessigpulver mit den Produktionsanlagen interagiert. Im Folgenden werden die häufigsten Probleme ihren jeweiligen Ursachen zugeordnet:

Ursache: Ungleichmäßiger Pulverfluss oder verschlissene Indexnocken im Kapselfüllmaschine Die

Auswirkungen: Feine Pulver mit schlechter Fließfähigkeit neigen dazu, sich im Trichter und in den Dosierbereichen zu verklumpen oder zu verhaken, was eine gleichmäßige Materialabgabe in die einzelnen Kapseln verhindert.

Ursache: Offene Drehteller, statische Elektrizität oder raue Pulverkontaktflächen ermöglichen es, dass ACV-Pulver Brücken bildet oder austritt. Gelatinekapsel-Füllmaschine Innenleben.

Auswirkungen: Verringert die Füllgenauigkeit, verunreinigt Maschinenteile und erhöht die Reinigungshäufigkeit.

Ursache Enge Zuführkanäle, enge Formöffnungen oder leicht klebriges Pulver erhöhen die mechanische Belastung während der Kapseltrennung.

Auswirkungen : Beschädigte oder deformierte Kapseln fallen bei der Qualitätskontrolle durch, unterbrechen die Produktion und führen zu Materialverschwendung.

Ursache Die Feuchtigkeitsempfindlichkeit von Apfelessig führt selbst bei geringster Luftfeuchtigkeit zu Verklumpungen des Pulvers in der Kapselmaschine.

Auswirkungen Tägliche Reinigung ist erforderlich, was Durchsatz und Effizienz verringert.

Ursache: Der Säuregehalt von Apfelessig kann ungeschützte Maschinenteile verschleißen oder korrodieren.

Auswirkungen Nicht säurebeständige Teile verschleißen schneller, was zu Leckagen, Hygieneproblemen und potenzieller Kontamination führen kann.

1. Ungenauigkeit bei der Pulverabfüllung

Verwenden Hochpräzisions-Kapselfüllmaschine Ausgestattet mit einem optischen Indexiersystem von Zeiss gewährleistet es eine stabile Positionierung und Dosiergenauigkeit von ≤3 %. Darüber hinaus sorgt der Füllmechanismus mit dreidimensionaler Justierung für eine gleichmäßige Belastung der Dosierscheibe und ermöglicht eine schnelle, präzise Füllgewichtskontrolle für eine gleichbleibende Kapselausbeute.

2. Pulverbrücken und -leckagen

Statten Sie die Kapselmaschine mit Doppeldichtungs-Drehtischen, vollständig geschlossenen Trichtern und elektropolierten Pulverkontaktflächen aus. Die Zwangszuführung verhindert Brückenbildung und reduziert das Austreten von Pulver in das Maschineninnere, wodurch ein sauberer Betrieb und ein stabiler Durchsatz gewährleistet werden.

3. Kapselbruch und -verformung

Die hochpräzise Formkonzentrizität ohne Versatz sorgt dafür, dass die Kapseln während des Betriebs perfekt zentriert bleiben und Kantenkontakt sowie Reibung vermieden werden. Dies verhindert Beschädigungen und Verformungen der Kapseln und gewährleistet eine reibungslose und stabile automatische Kapselabfüllung.

4. Hohe Reinigungsausfallzeiten

Ein integriertes Druckluft-Formreinigungssystem hält Ober- und Unterform größtenteils sauber. Die modulare Bauweise und der herausziehbare Füllstangenhalter ermöglichen einen schnellen, werkzeuglosen Wechsel auf verschiedene Größen, wodurch Reinigungszeiten verkürzt und Produktionsausfallzeiten minimiert werden.

5. Umgang mit Säure

Verwenden Sie für alle ACV-berührenden Komponenten der Kapselabfüllanlage säurebeständige Werkstoffe. Zuführungen, Drehtische und Dosierteile aus korrosionsbeständigem Edelstahl oder Spezialpolymeren gewährleisten langfristige Zuverlässigkeit, verhindern Leckagen und halten die Hygienestandards im Dauerbetrieb ein.

Dank jahrzehntelanger Erfahrung, speziell entwickelter Maschinen und umfassender technischer Unterstützung hilft Rich Packing Herstellern dabei, ACV-Kapseln in gleichbleibend hoher Qualität herzustellen.

Fachkompetenz und Compliance

■ Seit über 32 Jahren spezialisiert auf Kapsel- und Nahrungsergänzungsmittelausrüstung.

■ Vollständig konform mit den Normen ISO, CE, cGMP und SA8000.

Speziell entwickelte Kapselfüllmaschinen der NJP-Serie

■ Optisches Indexiersystem von Zeiss und CNC-gefräste Nutkurven für präzise Kapselbefüllung.

■ Patentierte Drehteller mit doppelter Abdichtung verhindern das Eindringen von Pulver und Brückenbildung.

■ Elektropolierte Dosierkomponenten zur Minimierung der Pulveranhaftung.

■ Hochpräzise Formkonzentrizität zur Reduzierung von Kapselbrüchen.

■ Optionale Vakuumförderer für die gleichmäßige Handhabung von ACV-Pulvern mit niedriger Fließfähigkeit.

■ Hochgeschwindigkeits-Kapselfüllmaschinen lassen sich von Forschungs- und Entwicklungschargen bis zur vollen Produktion skalieren, ohne Kompromisse bei Ausbeute oder Konformität einzugehen.

Umfassende Supportleistungen

■ Videos zur Maschineneinführung, Installation, Inbetriebnahme, Demontage und Wartung.

■ Ferndiagnose und Software-Updates für eine schnelle Fehlerbehebung.

■ Weltweiter Service mit Abdeckung in über 80 Ländern.

■ Technische Beratung zu Rezeptur, Kapselauswahl und feuchtigkeitsabweisender Verpackung zur Maximierung der Produktstabilität und Haltbarkeit.

F: Woran erkennt man, ob eine Apfelessigkapsel zuverlässig ist?

A: Achten Sie auf die Angabe der mg pro Portion, die Verfügbarkeit des Analysezertifikats, GMP-Erklärungen, die Rückverfolgbarkeit der Chargen und Stabilitätsdaten.

F: Welche Toleranz des Füllgewichts ist normal?

A: ±2–3 % bei Pulvern; Werte über ±5 % sind ein Warnsignal.

F: Werden durch die Modernisierung der Maschinen alle Probleme behoben?

A: Nein. Sie müssen es mit Anpassungen der Rezeptur, der Umgebungsbedingungen und der Standardarbeitsanweisungen kombinieren.

F: Ist eine spezielle Verpackung erforderlich?

A: Ja. Feuchtigkeitssperrende Flaschen, Trockenmittel und dicht verschlossene Blisterverpackungen sind für hygroskopische Puder unerlässlich.

Apfelessigkapseln sehen im Regal unscheinbar aus, aber für eine gleichbleibende Qualität ist Folgendes erforderlich:

■ Durchdachte Formulierung

■ Sorgfältige Prozesskontrolle

■ Speziell angefertigte Maschinen

Für Verbraucher bedeutet dies transparente Marken. Für Hersteller bedeutet es Investitionen in die richtige Ausrüstung und Unterstützung. Die Kapselfüllanlagen von Rich Packing sind auf die besonderen Herausforderungen der Apfelessigproduktion zugeschnitten und ermöglichen es Unternehmen, präzise, stabile und normkonforme Nahrungsergänzungsmittel herzustellen.

[1] Operation Supplement Safety (OPSS): Apfelessig in Nahrungsergänzungsmitteln

https://www.opss.org/article/apple-cider-vinegar-dietary-supplements

[2] Fortune Business Insights: Marktgröße, Marktanteil und Wachstum des Apfelessigmarktes

[3] PubMed / PMC: Metaanalyse: Einfluss der Apfelessig-Einnahme auf die Körperzusammensetzung (2025)