Apropos Luftpolsterfolie: Viele Menschen wissen vielleicht nicht, was das ist. Allerdings Blisterverpackung Diese Verpackungsmethode hat in verschiedenen Bereichen unseres täglichen Lebens Einzug gehalten. Beispielsweise sind Blisterverpackungen überall in unserem Leben zu finden, von kleinen Läden bis hin zu großen Supermärkten, Baumärkten, Krankenhäusern, Apotheken, Schreibwaren und Produkten des täglichen Bedarfs. Warum ist diese Verpackung dann so beliebt und weit verbreitet? Lassen Sie mich im Folgenden ausführlich erklären, was Blisterverpackungen sind und welche Vor- und Nachteile sie haben.

Blisterverpackungen sind eine moderne und weit verbreitete Verpackungsmethode, die sich besonders für kleine Güter wie Medikamente/Gesundheitsprodukte, medizinische Einweggeräte, feste und flüssige Lebensmittel, Kosmetika, biochemische und chemische Produkte des täglichen Bedarfs, Schreibwaren, Kleinteile, Spielzeug, Autoteile, Saatgut, elektronische Produkte und andere Produkte eignet. Das Grundprinzip der Blisterverpackungstechnologie besteht darin, das Produkt in einem vorgeformten transparenten Kunststoffblister einzukapseln und anschließend den Blister und die Rückwand (Bodenplatte) miteinander zu versiegeln. Im Folgenden gebe ich Ihnen eine detaillierte Einführung in die Blisterverpackung.

Der Blister wird üblicherweise aus Kunststoff (PVC) oder Metall (Aluminiumfolie) durch Erhitzen im Blasform- oder Pressverfahren hergestellt, wodurch ein oder mehrere erhabene Hohlräume zur Aufnahme des Produkts entstehen. Der Blister kann auch an die Form der Produktform angepasst werden, um eine spezielle Hohlraumform für unterschiedliche Anforderungen zu schaffen. Im Folgenden werden gängige Materialien für das Blisterformen vorgestellt.

Polyvinylchlorid (PVC): hohe Transparenz, leicht zu formen, günstig.

Polyethylenterephthalat (PET): gute Barriere, starke chemische Beständigkeit.

Polypropylen (PP): Gute Hitzebeständigkeit, geeignet für Sterilisation bei hohen Temperaturen.

Aluminiumfolie: das am häufigsten verwendete Backplane-Material, hervorragende Barriere, nach dem Versiegeln leicht zu öffnen.

Aluminium-Kunststoff-Verbundwerkstoff: kombiniert die Vorteile von Kunststoffboxen aus Aluminiumfolie.

Für die Rückwand von Blisterverpackungen für Medikamente wird üblicherweise Aluminiumfolie verwendet. Je nach Bedarf kann aber auch Kunststoff, Karton, Dialysepapier oder andere Verbundmaterialien verwendet werden, da auf die Träger- und geschlossene Oberfläche des Blisters auch Anzeigeinformationen wie Markenname und Logo, Informationen zu Werbeaktionen, Produktinformationen, Gebrauchsanweisungen, Warnhinweise usw. gedruckt werden können.

Der Verbindungsteil zwischen der Blisterkappe und der Rückplatte wird durch Heißsiegeln, Kaltsiegeln oder Kleben fest miteinander verbunden, um die Dichtheit und Integrität der Verpackung zu gewährleisten.

Bei der Auswahl der Blisterverpackung sollten bei der Materialwahl eine Reihe von Faktoren berücksichtigt werden, wie z. B. Produkteigenschaften, Größe und Form, Haltbarkeitsanforderungen, Produktionsprozesse, Umweltbelastung, gesetzliche Anforderungen, Kosten, Umweltfaktoren und Verbraucherfreundlichkeit.

Blisterverpackungen sind eine praktische und wirtschaftliche Verpackungslösung, die den Anforderungen verschiedener Branchen gerecht wird, um Produkte zu schützen, zu präsentieren und eine Massenproduktion zu ermöglichen. Lassen Sie uns als Nächstes verstehen, welche Vorteile Blisterverpackungen bieten.

Durch die transparente Luftpolsterfolie können Kunden das Produkt direkt sehen und die Produktinformationen vollständig anzeigen, wodurch das Vertrauen der Kunden gestärkt wird. Dies verbessert nicht nur die Kaufquote der Kunden, sondern reduziert auch die Probleme des Kundendienstes.

Blisterverpackungen bieten aufgrund ihres Materials und der erhabenen Struktur einen sicheren Schutzraum für das Produkt und reduzieren so die Schäden, die während des Transports und der Lagerung durch das Produkt verursacht werden können. Gewährleistet die Unversehrtheit des Produkts in den Händen des Kunden.

Aufgrund ihres Materials verfügt die Blisterverpackung über eine hervorragende Barrierewirkung, ist wirksam feuchtigkeits-, licht- und oxidationsbeständig, reduziert den Kontakt des Produkts mit der Außenwelt, erhält die Stabilität des Produkts und verlängert so die Haltbarkeit des Produkts.

Die transparente Blisterpackung und die mit Aluminiumfolie versiegelte Rückseite erleichtern das Erkennen von Manipulationsspuren und gewährleisten die Produktintegrität und -sicherheit vom Kaufzeitpunkt bis zum Verbraucher. Dies kann das Vertrauen der Verbraucher in das Produkt deutlich stärken und so den Produktabsatz steigern.

Jede einzelne Blisterpackung ermöglicht die individuelle Versiegelung des Produkts. Das Öffnen einer Blisterpackung beeinträchtigt die anderen Blisterpackungen nicht. Dadurch wird das Risiko einer Kreuzkontamination verringert und die langfristige Verwendung durch Verbraucher erleichtert, da durch das Öffnen einer Verpackung die Qualität und Haltbarkeit anderer unabhängiger Blisterprodukte nicht beeinträchtigt wird.

Da die Blisterverpackung leicht und glatt ist und sich durch das Design leicht aufreißen lässt, können Verbraucher die Produkte der gesamten Packung bequem je nach Bedarf in mehrere unabhängige kleine Pakete aufteilen, was den täglichen Gebrauch und die Lagerung erleichtert.

Bei Arzneimitteln und Gesundheitsprodukten ermöglicht das unabhängige Blisterdesign den Verbrauchern einen bequemen Zugriff bei Bedarf, was den Patienten hilft, die Arzneimittel entsprechend der ärztlichen Empfehlung über einen langen Zeitraum einzunehmen.

Die Rückwand der Blisterverpackung bietet ausreichend Platz zum Aufdrucken von Anzeigeinformationen auf der Rückseite, wie z. B. Markeninformationen, Produktinformationen, Gebrauchsanweisungen, Vorsichtsmaßnahmen, Barcode/zweidimensionaler Code zur Rückverfolgbarkeit von Informationen.

Blisterverpackungen bestehen im Allgemeinen aus Kunststoff (PVC) und werden durch Erhitzen, Blasformen oder Pressformen geformt, um den Anforderungen an Form, Größe und individuelles Design verschiedener Produkte gerecht zu werden. Die Rückseite der Blisterverpackung kann vollständig bedruckt werden, um verschiedene Informationen anzuzeigen, die Eigenschaften verschiedener Produkte und Werbeinformationen hervorzuheben, die Aufmerksamkeit der Kunden zu erregen und die Kaufbereitschaft der Kunden zu steigern.

Das standardisierte Design der Blisterverpackung ist für die Massenproduktion geeignet und die Produktion im großen Maßstab kann mit automatisierten Produktionsliniengeräten wie Aluminium-Kunststoff-Blisterverpackungsmaschinen erreicht werden, wodurch die Stückkosten und eine große Anzahl an Personalkosten gesenkt werden. Blisterverpackungsmaschine Integriert Materialförderung, Erhitzen oder Kaltpressen, Füllen (Drehscheibenzufuhr, Orbitalstationszufuhr, mechanische Handzufuhr usw.), Heißsiegeln, Stanzen und Schneiden und bildet so einen vollständig automatischen Produktionsprozess. Dieses integrierte Design vereinfacht den Produktionsprozess erheblich und reduziert die Materialhandhabung und manuelle Eingriffe in die Zwischenglieder, wodurch die Produktionseffizienz deutlich verbessert wird.

Blisterverpackungen werden in diesem Verfahren häufig verwendet, können aber aufgrund ihrer Mängel nicht ignoriert werden. Lassen Sie uns diese Informationen im Folgenden gemeinsam verstehen, damit Sie die Verwendung besser verstehen und auswählen können.

Die meisten Blisterverpackungsmaterialien bestehen häufig aus Verbundwerkstoffen, was dazu führt, dass sich ihre Bestandteile nur schwer trennen und recyceln lassen. Herkömmliche Kunststoffe zersetzen sich in der Natur nur schwer, und die langfristige Verwendung verursacht eine große Umweltverschmutzung. Dieses Problem hat auch zur kontinuierlichen Weiterentwicklung und Aktualisierung von Materialien geführt, um den Umweltschutz zu gewährleisten.

Beim Verpacken kleinerer Produkte wie Medikamente ist die Blisterverpackung im Vergleich zu Beuteln oder Flaschen aufgrund der größeren Einheitsfläche und der relativ festen Verpackungskosten pro Tablettenplatte nicht wesentlich günstiger, da die Stückkosten bei einer großen Stückzahl nicht signifikant sinken und die Verpackungsmaterial- und Verbrauchskosten höher sind. Da unterschiedliche Produkte Formen unterschiedlicher Größe und Form benötigen, sind die Kosten für die Änderung der Form nach Fertigstellung relativ hoch, sodass Blisterverpackungen nicht für die Kleinserien- oder Sonderanfertigungsproduktion geeignet sind.

Blisterverpackungen benötigen mehr Platz, da ein erhöhter Hohlraum für ein einzelnes Medikament und ein Teil der Rückwand des erweiterten Sicherheitsbereichs gebildet werden muss, was bei gleicher Medikamentenanzahl zu mehr Platz führt. Dadurch wird mehr Platz für Versand und Produktlagerung benötigt.

Für ältere Menschen und Verbraucher mit unbeweglichen Händen kann es schwierig sein, das Arzneimittel zu entnehmen. Und Blisterverpackungen können aufgrund von Erhitzung oder Pressformen, die zu scharfen Kanten der Blisterplatte führen, bei unsachgemäßer Handhabung beim Öffnen leichte Kratzer verursachen.

Aufgrund der manipulationssicheren Eigenschaften von Blisterverpackungen kann es bei unsachgemäßer Handhabung der Blisterverpackungsprodukte während der Produktion, des Transports und der Lagerung zu irreparablen Schäden durch Extrusion kommen und sie können in der Regel nur noch verschrottet werden, was zu einer gewissen Zunahme der Fertigprodukte und des Abfalls führt.

Aufgrund ihrer breiten Anwendbarkeit, ihres guten Schutzes und ihrer Präsentation können Blisterverpackungen die Persönlichkeit des Produktdesigns hervorheben. Sie werden in verschiedenen Branchen häufig verwendet und finden tiefgreifende Anwendung in allen Aspekten unseres Lebens. Im Folgenden werden Ihnen Blisterverpackungen in jedermanns Leben und in allen Branchen sowie typische Produkte gezeigt.

Blisterverpackungen werden in der Pharma- und Gesundheitsbranche häufig für Einzeldosisverpackungen verwendet, da sie Patienten die genaue Einnahme von Medikamenten gemäß ärztlicher Anweisung erleichtern. Der erhöhte Hohlraum der Blisterverpackung schützt die Medikamente zudem, und die gute Barrierewirkung verhindert effektiv Feuchtigkeit und Oxidation, wodurch die Wirksamkeit und Haltbarkeit der Medikamente verlängert wird. Dank des manipulationssicheren, transparenten und gut sichtbaren Designs und der Möglichkeit, detaillierte Medikamenteninformationen auf die Rückseite zu drucken, werden Blisterverpackungen von den meisten Pharmaunternehmen gerne verwendet. Zu den gängigen Blisterverpackungen für medizinisches Bedarfsmaterial gehören Tabletten, Kapseln, orale Flüssigkeiten, Einwegspritzen, Insulininjektionen usw.

Blisterverpackungen für Körperpflegeprodukte bieten den Vorteil, dass das Einwegdesign Hygiene und Versiegelung garantiert und das Produkt sauber und frisch hält. Beispielsweise können ätherische Öle für die Reisepflege dank ihrer Tragbarkeit auf Reisen transportiert werden, sodass die Produkte stets optimal geschützt sind. Das transparente Design zeigt die Produkteigenschaften intuitiv, während die hervorragende Feuchtigkeitsbeständigkeit die Haltbarkeit verlängert und die Stabilität und Sicherheit des Produkts gewährleistet. Ob für den täglichen Gebrauch oder unterwegs – Blisterverpackungen sind eine schöne und praktische Lösung. Zu den gängigen Blisterverpackungen für Körperpflegeprodukte zählen Pflegeessenzen, ätherische Öle, Kompressionsmasken, Mundwasserkapseln und verschiedene Musterverpackungen für Pflegeprodukte.

Blisterverpackungen werden für Lebensmittel verwendet, um die Haltbarkeit zu verlängern, die Lebensmittel frisch zu halten und den Transport und Verzehr zu erleichtern. Der Feuchtigkeitsschutz schützt Lebensmittel vor Feuchtigkeit, das transparente Design zieht Verbraucher an. Blisterverpackungen eignen sich für kleine Mengen und hochwertige Lebensmittel, was die Produktqualität verbessert und den Absatz steigert. Typische Blisterverpackungen für Lebensmittel sind Süßigkeiten, Kekse, Ketchup, Marmelade, Honig, Schokolade, Gewürze und andere feste und flüssige Produkte.

Blisterverpackungen für elektronische Produkte: Transparente Blisterverpackungen machen elektronische Produkte sicher und sichtbar, fördern die Produktidentifikation und das Werbedesign auf der Rückseite. Darüber hinaus kann die Struktur der Blisterverpackung auch eine gute Rolle beim Schutz vor Feuchtigkeit und anderen Einflüssen spielen, um die Leistung elektronischer Produkte, ihre Qualitätsstabilität und ihren physischen Schutz vor Transportrisiken zu gewährleisten. Zu den gängigen Blisterverpackungen für elektronische Produkte gehören Speicherkarten, USB-Sticks, Knopfbatterien und verschiedene kleine elektronische Geräte.

Blisterverpackungen für Eisenwaren können die Oxidation von Metallprodukten wirksam verhindern und so Rostbildung verhindern. Transparente Blister erleichtern Verbrauchern die Identifizierung der benötigten Werkzeuge und ermöglichen so einen effizienten Einkauf. Zu den üblichen Eisenwarenprodukten in Blisterverpackungen zählen verschiedene Kleinwerkzeuge, Schraubendreher, Schrauben und Muttern, Dichtungen, Zangen und Schraubenschlüssel sowie Beleuchtungszubehör.

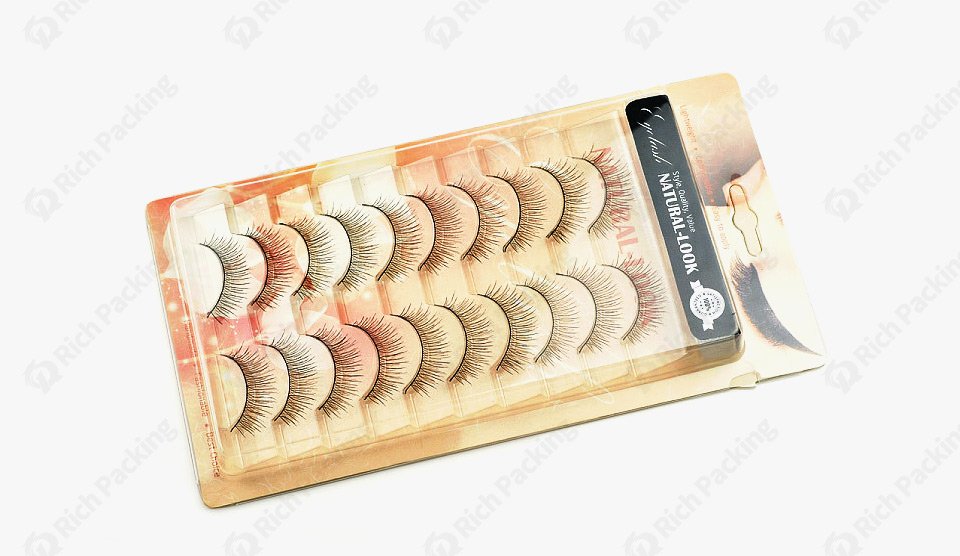

Einwegverpackungen gewährleisten Hygiene, versiegeltes Design hält die Produkte frisch, transparentes Design zeigt Farbe und Wirkung des Produkts, leicht zu tragen, geeignet für Reisen oder zum Mitnehmen, geeignet für Schönheitswerkzeuge, die sauber gehalten werden müssen. Zu den üblichen Blisterverpackungen für Kosmetikprodukte gehören falsche Wimpern, Nagelkunst, Augenbrauenstift, Mascara und Zubehör für Schönheitsgeräte

Durch die obige ausführliche Einführung in Blisterverpackungen haben wir ein grundlegendes Verständnis der Grundlagen von Blisterverpackungen, ihrer Vor- und Nachteile sowie ihrer gängigen Anwendungen in der Branche und bei Produkten. Anschließend können Sie nach umfassender Prüfung die geeigneten Blisterverpackungsmethoden und -materialien entsprechend der Art und den Eigenschaften Ihrer eigenen Produkte auswählen, um den Bedürfnissen der Verbraucher gerecht zu werden. Sie können weiterhin auf unsere Verpackungen achten. Im Folgenden erfahren Sie mehr über Produktverpackungen. Vielen Dank für Ihre Aufmerksamkeit.