Medikamente und ihre vielfältigen Verpackungsformen stehen seit jeher im Fokus der Pharmaindustrie. Unter den vielen Arten der Pillenverpackung nimmt die Blisterverpackung zweifellos eine wichtige Position ein, und die Schlüsselausrüstung für diese Verpackung, die Blisterverpackungsmaschine , spielt eine zentrale Rolle in der Pharma- und Verpackungsindustrie.

Blisterverpackungen, auch Blasformverpackungen genannt, sind eine Verpackungsform, bei der Produkte mithilfe eines speziellen Geräts in eine Blistermulde aus Kunststoff verpackt werden. Diese Verpackungsform schützt das Produkt nicht nur vor Beschädigungen, sondern verhindert auch, dass es verunreinigt wird.

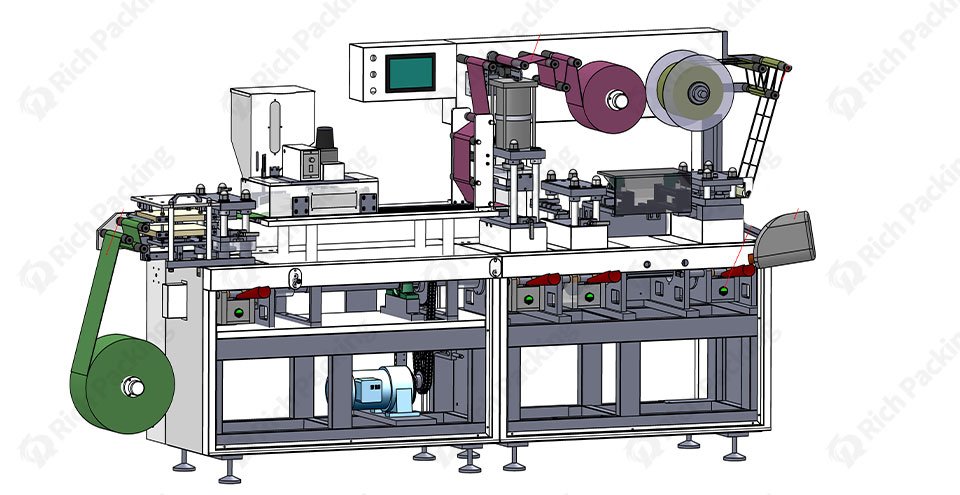

Funktionsprinzip der Blisterverpackungsmaschine

Als häufig verwendetes Verpackungsgerät ist sein Funktionsprinzip relativ komplex, der Prozess jedoch klar und prägnant. Hier sind einige Beschreibungen des grundlegenden Funktionsprinzips des Blisterverpackungsmaschine .

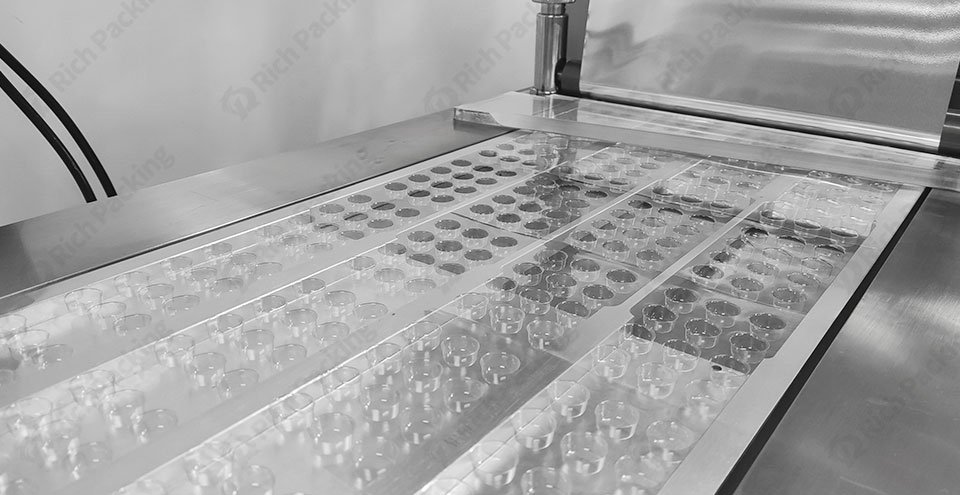

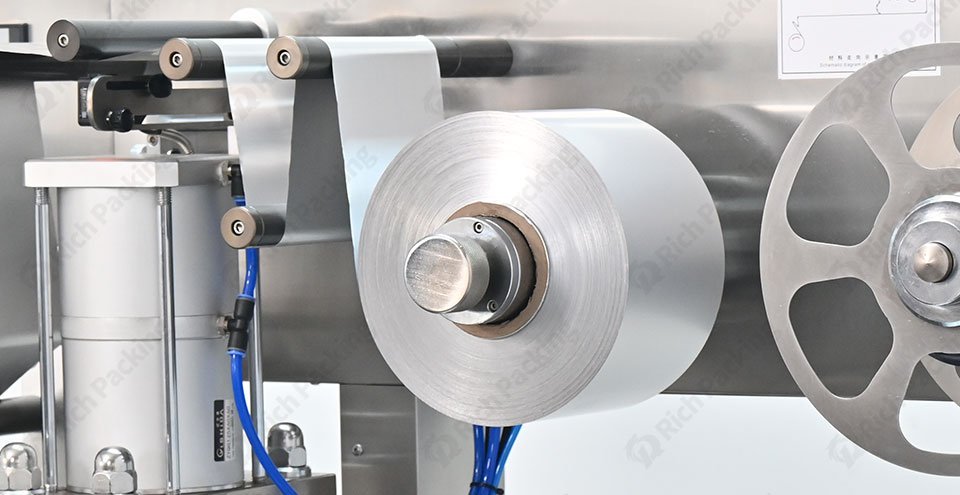

Zunächst wird das Verpackungsmaterial in die Blisterverpackungsmaschine eingebracht. Durch das Heizsystem wird die Kunststofffolie auf eine ausreichende Temperatur erhitzt, um sie zu erweichen. Anschließend wird die erhitzte Kunststofffolie mithilfe einer speziellen Form aufgeblasen, um eine Blisterschale mit einer bestimmten Tiefe und Form zu bilden. Für besonders hohe Tiefenanforderungen kann zusätzlich eine physikalische Vertiefungsvorrichtung hinzugefügt werden.

Nach der Herstellung der Blisterhülle wird das Produkt automatisch in jeden Luftblister gefüllt. Dies geschieht über ein automatisches Zuführ- und Fördersystem oder per Hand. Bei einem automatischen System ist während des Zuführvorgangs ein präzises Positionierungssystem erforderlich, um sicherzustellen, dass das Produkt präzise in jeden Blister gefüllt wird.

Nach dem Befüllen des Produkts legt die Maschine eine weitere Schicht Kunststofffolie oder Papier darauf und verschweißt diese mithilfe eines Heißsiegelsystems, um das Produkt zwischen den beiden Materialschichten zu schützen. Es ist zu beachten, dass Temperatur und Dauer des Heißsiegelns großen Einfluss auf die Qualität der Verpackung haben. Die allgemeine PVC-Temperatur beträgt 160 Grad Celsius, da eine zu hohe Temperatur oder eine zu lange Verweildauer das Verpackungsmaterial beschädigen kann, während eine zu niedrige oder zu kurze Verweildauer die Stabilität der Heißsiegelung beeinträchtigen kann.

Abschließend wird jedes verpackte Produkt von der Stanzstation zu einer eigenständigen Blisterverpackung ausgeschnitten. Auch dieser Schritt erfordert ein präzises Positionierungssystem, um die Genauigkeit und Sauberkeit des Schnitts zu gewährleisten. Bei einer Fehlausrichtung wird das ursprünglich verpackte Material direkt geschnitten und die gesamte Umverpackung samt Produkt entsorgt.

Der Betrieb der Blisterverpackungsmaschine muss verschiedene Faktoren wie Materialeigenschaften, Formdesign, mechanische Ausrüstung und automatische Steuerung umfassend berücksichtigen. Ihre Wirkung wirkt sich direkt auf die Qualität, das Aussehen und die Produktionseffizienz der verpackten Produkte aus. Daher ist es sehr wichtig, das Funktionsprinzip und die Bedienung der Blisterverpackungsmaschine zu kennen und zu beherrschen, um die Produktionseffizienz und Produktqualität zu verbessern.

Blisterverpackungsmaschinen lassen sich je nach Einsatzzweck im Wesentlichen in folgende Kategorien unterteilen:

geeignet für Start-up-Unternehmen oder Kleinserienproduktion, einfache Bedienung, geringe Kosten, Heißsiegeln und Schneiden erfordern einen hohen Aufwand, daher ist es nicht nur zeit- und arbeitsintensiv, sondern auch ineffizient.

Geeignet für kleine und mittlere Unternehmen. Einige Vorgänge müssen manuell ausgeführt werden, z. B. das manuelle Einfüllen von Materialien in Blister usw. Die Kosten sind moderat und die Arbeitseffizienz und -qualität sind höher als bei manuellen Blisterverpackungsmaschinen.

Geeignet für die Großserienproduktion, alle Arbeitsschritte können automatisch ausgeführt werden, hohe Produktionseffizienz, niedrige Arbeitskosten und maximale Garantie für stabile und gleichbleibende Verpackungsqualität.

PVC ist hochtransparent und zeigt den Zustand des Produkts in der Verpackung deutlich an. Seine physikalischen Eigenschaften sind stabil und können die Auswirkungen der äußeren Umgebung auf das Produkt wirksam verhindern. Darüber hinaus weist PVC eine gute Verarbeitungsleistung und eine starke Anpassungsfähigkeit auf, sodass es zu einem der am häufigsten verwendeten Verpackungsmaterialien in Blisterverpackungsmaschinen geworden ist.

Im Vergleich zu PVC ist PET umweltfreundlicher, da es recycelt und wiederverwendet werden kann. Gleichzeitig weist PET eine höhere Transparenz und Härte auf, was dem Produkt einen besseren Schutz bietet. Allerdings ist die Verarbeitungstemperatur von PET höher und die Anforderungen an die Ausrüstung relativ hoch.

PP wird häufig für Produktverpackungen verwendet, die hohen Temperaturen standhalten müssen. Das Material verfügt über eine hervorragende Hitzebeständigkeit und hält hohen Temperaturen in Umgebungen wie Mikrowellenherden stand. Obwohl PP eine geringe Transparenz aufweist, ist es aufgrund seiner guten Hitzebeständigkeit und Luftbarriereeigenschaften in bestimmten Anwendungsfällen ein ideales Verpackungsmaterial.

PS ist ein Kunststoff mit hoher Härte, guter Transparenz und einfacher Formbarkeit. Es wird häufig zur Herstellung harter und komplexer Verpackungsprodukte verwendet. Seine Hitzebeständigkeit und Schlagzähigkeit sind jedoch relativ gering, sodass es im Allgemeinen zur Verpackung von Produkten verwendet wird, die keinen hohen Temperaturen und Stößen standhalten müssen.

Als Schlüsselgerät zur Herstellung von Blisterverpackungen spiegelt sich die Bedeutung der Blisterverpackungsmaschine hauptsächlich in den folgenden Aspekten wider:

Ja, Blisterverpackungen gelten heute weltweit als sicher. Sie bieten die folgenden Vorteile, um die Sicherheit der verpackten Produkte zu gewährleisten.

Andererseits sind einige in Blisterverpackungen verwendete Kunststoffarten möglicherweise nicht für alle Produktarten geeignet, beispielsweise für Produkte, die empfindlich auf bestimmte Kunststoffrückstände reagieren. Insgesamt gelten Blisterverpackungen als sichere Möglichkeit, eine Vielzahl von Produkten zu verpacken.

Blistermaschinen werden in vielen Branchen und Bereichen zum Verpacken unterschiedlichster Produkte eingesetzt. Hier sind einige gängige Produkttypen, die mit Blistermaschinen verpackt werden.

In der Pharmaindustrie werden Blistermaschinen hauptsächlich zum Verpacken von Medikamenten wie Pillen, Kapseln, Tabletten usw. verwendet. Durch die Blisterverpackung können die Medikamente nicht nur vor äußerer Verunreinigung geschützt werden, ihre Frische und Wirksamkeit bleiben erhalten, sondern es ist für den Verbraucher auch bequem, sie entsprechend der genauen Dosierung einzunehmen.

In der Lebensmittelindustrie werden Blistermaschinen häufig zum Verpacken verschiedener Süßigkeiten, Pralinen, Kekse, Tiefkühlkost usw. verwendet. Durch transparente Blisterverpackungen können Verbraucher deutlich erkennen, wie das Lebensmittel aussieht, und der Verpackungsprozess kann das Lebensmittel nicht nur wirksam vor Beschädigungen schützen, sondern auch seine Frische bewahren.

In der Elektronikindustrie werden Blistermaschinen häufig zum Verpacken verschiedener kleiner und teurer oder zerbrechlicher elektronischer Produkte wie USB-Sticks, Speicherkarten, SIM-Karten usw. verwendet. Transparente Blisterverpackungen können elektronische Produkte nicht nur vor Beschädigungen schützen, sondern ermöglichen es den Verbrauchern auch, das Produkt beim Kauf deutlich zu sehen.

Auch in der Branche der täglichen Bedarfsartikel werden Blistermaschinen häufig eingesetzt, beispielsweise zum Verpacken von Zahnbürsten, Rasierapparaten, Messern, Spielzeug und anderen Produkten. Blisterverpackungen schützen Produkte nicht nur vor Beschädigungen, sondern ermöglichen es den Verbrauchern auch, beim Kauf das tatsächliche Aussehen des Produkts zu sehen.

Blisterverpackungsmaschinen sind in vielen Branchen unverzichtbar. Das Verständnis ihrer Funktionsweise und Anwendungsmöglichkeiten hilft Unternehmen, intelligentere Entscheidungen zu treffen. Ob Unternehmer oder bestehendes Unternehmen – Blasformverpackungsmaschinen stärken Ihren Produktionsprozess. Wir sind ein Hersteller, der seit langem Pharma- und Verpackungsmaschinen an Fortune 500-Unternehmen liefert. Wenn Sie eine Blisterverpackungsmaschine benötigen, kontaktieren Sie uns bitte. Kontakt .