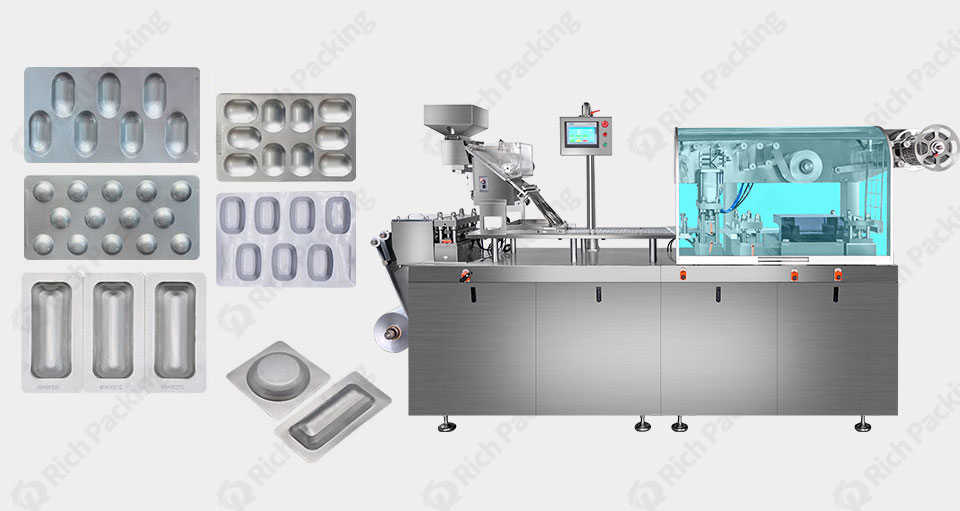

Alu-Blisterverpackungsmaschine Bezieht sich im Allgemeinen auf mechanische Geräte zur Herstellung von Blisterverpackungen aus Aluminiumfolie. Diese Art von Verpackungsmaschine unterscheidet sich von der herkömmlichen Aluminium-Kunststoff-Blisterverpackungsmaschine, die PVC (Polyvinylchlorid) oder andere Kunststofffolien als Bodenmaterial verwendet, während die Aluminium-Aluminium-Blisterverpackungsmaschine zwei Schichten Aluminiumfolie verwendet, um den Blisterbehälter zu bilden. Daher wird sie auch als Doppel-Aluminium-Blisterverpackungsmaschine bezeichnet.

Material: Zwei Lagen Aluminiumfolie werden verwendet in Blisterverpackungsmaschine , und andere Barriereschichten können in der Mitte eingefügt werden, um die Gesamtbarriereleistung der Verpackung zu verbessern.

Versiegelung: Aufgrund der hervorragenden Barriereeigenschaften der Aluminiumfolie können Aluminium-Aluminium-Blisterverpackungen einen besseren Schutz vor dem Eindringen von Sauerstoff, Feuchtigkeit und Licht bieten und so die Haltbarkeit von Medikamenten verlängern.

Anwendung: Blisterverpackungsmaschine, geeignet zum Verpacken von Medikamenten und hochwertigen, umweltempfindlichen Artikeln.

Sicherheit: Die Aluminiumfolie der Blisterverpackungsmaschine bricht nicht so leicht und bietet zusätzlichen physischen Schutz.

Das Funktionsprinzip der Aluminium-Aluminium-Blisterverpackungsmaschine ähnelt dem der Aluminium-Kunststoff-Blisterverpackungsmaschine, der Hauptunterschied liegt jedoch in den verwendeten Materialien und der Art der letztendlich gebildeten Blistern.

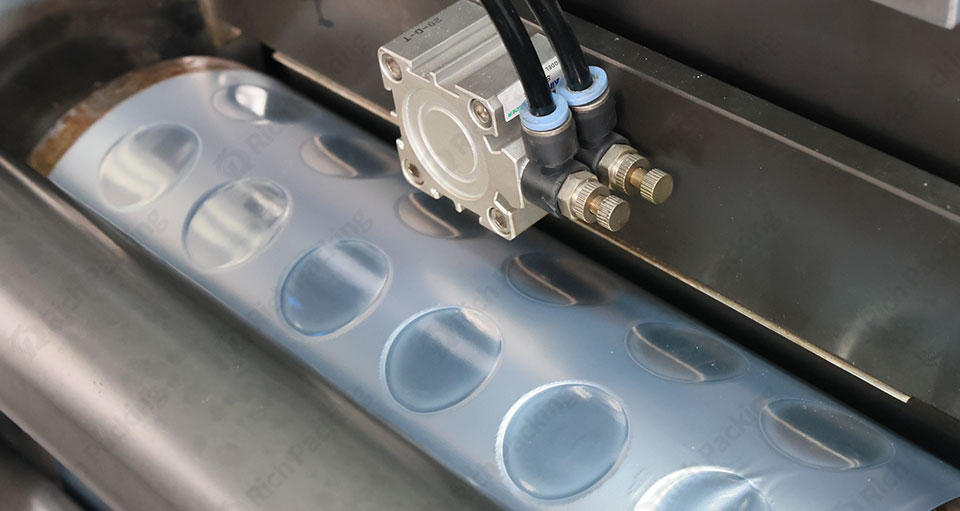

1. Kaltverformung: Eine Schicht Aluminiumfolie wird durch eine speziell entwickelte Vertiefungsform gepresst, um unter Überdruck eine Blase zu bilden. Blisterverpackungsmaschine .

2. Befüllen: Geben Sie die Medikamentenpartikel oder Tabletten in den bereits geformten Blister in der Blisterverpackungsmaschine.

3. Heißsiegeln in der Blisterverpackungsmaschine: Verwenden Sie eine weitere Schicht Aluminiumfolie, um den Blister mit dem Arzneimittel abzudecken, und versiegeln Sie die beiden Schichten Aluminiumfolie durch ein Heißsiegelgerät miteinander, um eine versiegelte Blistereinheit zu bilden.

4. Schneiden: Abschließend wird die Blistereinheit durch eine Schneidevorrichtung in einzelne oder endlose Blisterblätter geschnitten. Blisterverpackungsmaschine .

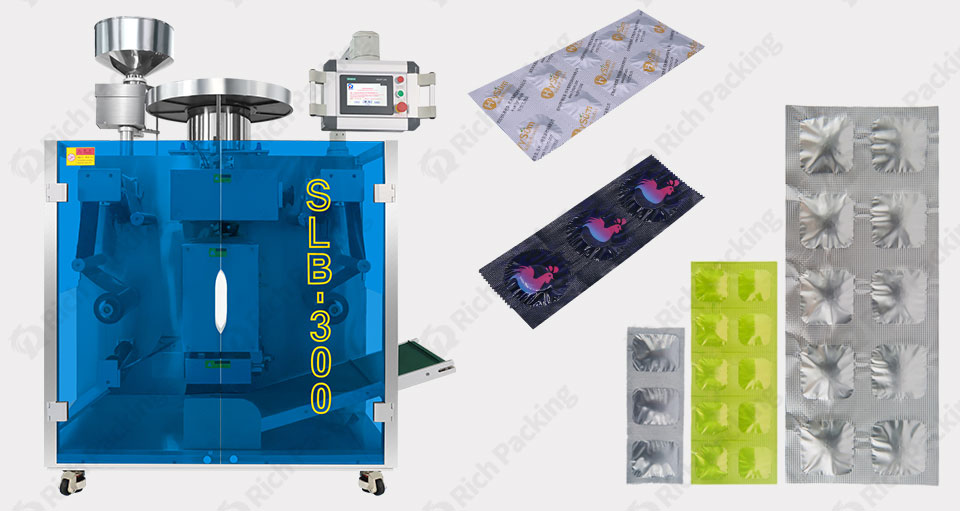

Eine weitere Art von Aluminium-Aluminium-Streifenverpackungsmaschine ist die weiche Doppel-Aluminium-Verpackungsmaschine. Streifenverpackungsmaschinen sind mechanische Geräte, die speziell für die Produktverpackung in der Pharma-, Lebensmittel-, Kosmetik- und anderen Industrien eingesetzt werden. Diese Streifenverpackungsmaschine wird üblicherweise verwendet, um feste Produkte (wie Tabletten, Kapseln usw.) zwischen zwei Lagen Aluminiumfolie zu verkapseln und so eine versiegelte Blisterverpackung zu bilden. S Reiseverpackungsmaschine Verpackungsmaschinen aus weichem Doppelaluminium sind aufgrund ihrer hohen Effizienz, ihres hohen Automatisierungsgrades und ihrer einfachen Bedienung beliebt.

1. Hoher Automatisierungsgrad: Die Streifenverpackungsmaschine kann den gesamten Verpackungsprozess, einschließlich Produktverteilung, Positionierung, Verpackung, Versiegelung und Schneiden, automatisch abschließen.

2. Hohe Effizienz von Streifenverpackungsmaschine : Durch fortschrittliche Steuerungssysteme kann die Verpackungsmaschine für weiche Doppelaluminiumstreifen einen Hochgeschwindigkeitsbetrieb erreichen und die Produktionseffizienz verbessern.

3. Genauigkeit: Weiche Doppel-Aluminium-Verpackung Streifenverpackungsmaschine ist Sie sind in der Regel mit Sensoren und Kontrollsystemen ausgestattet, um eine genaue Positionierung der Produkte und eine einheitliche Verpackung zu gewährleisten.

4. Flexibilität: Weiche Doppelaluminium-Verpackungsmaschinen können die Größe der Verpackungsmaterialien und die Anordnung der Produkte nach Bedarf anpassen, um sich an Produktverpackungen unterschiedlicher Spezifikationen anzupassen.

5. Streifenverpackungsmaschine Einfache Bedienung: Viele Verpackungsmaschinen für weiche Doppelaluminiumstreifen verwenden eine Touchscreen-Bedienoberfläche, die die Bedienung intuitiver und einfacher macht.

6. Einfache Wartung: Einige Streifenverpackungsmaschine Die Verpackungsmaschinen aus weichem Doppel-Aluminium sind modular aufgebaut und ermöglichen so eine einfache Wartung und Reinigung.

1. Produktzufuhr: Das zu verpackende Produkt wird durch die Zufuhrvorrichtung in den Arbeitsbereich der Streifenverpackungsmaschine zugeführt.

2. Positionierung und Ausrichtung: Automatisches Erkennen und Anpassen der Position und Richtung des Produkts durch Sensoren und andere Geräte, um eine genaue Positionierung der Verpackung zu gewährleisten.

3. Zufuhr des Verpackungsmaterials: Die Verpackungsmaschine für weiche Doppel-Aluminium-Verpackungsstreifen führt das Verpackungsmaterial (normalerweise ein Verbundmaterial aus weichem Kunststoff und Aluminiumfolie) kontinuierlich von der Rolle zum Arbeitsbereich zu.

4. Formen: Das Aluminiumfolienmaterial wird durch Erhitzen und Druckbeaufschlagen in eine Blisterform gebracht, um das Produkt zu halten.

5. Befüllen: Füllen Sie das Produkt in den geformten Blister in Streifenverpackungsmaschine .

6. Heißsiegeln: Verwenden Sie eine weitere Schicht Aluminiumfolie, um die Oberseite des Produkts abzudecken, und versiegeln Sie die beiden Materialschichten mithilfe eines Heißsiegelgeräts miteinander.

7. Chargennummer drucken: Drucken Sie die Produktionschargennummer, das Verfallsdatum und andere Informationen auf die Verpackung.

8. Schneiden: Schneiden Sie die Blisterfolie nach vorgegebenen Vorgaben in einzelne oder durchgehende Verpackungseinheiten.

9. Ausgabe des fertigen Produkts: Das fertige Produkt verlässt die Streifenverpackungsmaschine und ist bereit für den nächsten Verarbeitungsschritt oder gelangt direkt in die Umlaufverbindung.

Lebensmittelindustrie: Streifenverpackungsmaschine geeignet zum Verpacken kleiner Lebensmittel wie Süßigkeiten und Schokolade.

Kosmetikindustrie: Wird zum Verpacken kleiner Kosmetika wie Lippenstift, Nagellack usw. verwendet.

Aluminium-Aluminium-Blisterverpackungsmaschinen und Streifenverpackungsmaschinen werden aufgrund ihrer hervorragenden Leistung, ihres breiten Anwendungsspektrums und ihrer einzigartigen Eigenschaften in zahlreichen Branchen eingesetzt und spielen eine wichtige Rolle im Bereich der Industrieverpackung. Hier sind einige der Hauptvorteile von Aluminiumfolienverpackungen:

1. Hervorragende Barriereeigenschaften: Aluminiumfolie kann Licht, Sauerstoff, Feuchtigkeit und andere Gase wirksam blockieren, was besonders wichtig für Produkte ist, die lange haltbar sein müssen, wie Lebensmittel und Medikamente.

2. Leichtigkeit: Aluminiumfolie ist sehr leicht und dünn, was den Transport in Aluminiumfolie verpackter Produkte erleichtert und zur Senkung der Logistikkosten beiträgt.

3. Starke Plastizität: Aluminiumfolie kann in verschiedenen Formen und Größen hergestellt werden, die für die Verpackungsanforderungen verschiedener Produkte geeignet sind.

4. Gute Heißsiegelleistung: Aluminiumfolie lässt sich leicht mit anderen Materialien verbinden und kann eine stabile Heißsiegelschicht bilden, um eine gute Versiegelung der Verpackung zu gewährleisten.

5. Korrosionsbeständigkeit: Aluminiumfolie weist eine gute Beständigkeit gegenüber den meisten Chemikalien auf, mit Ausnahme einiger starker Säuren und Laugen, sodass sie zum Verpacken von Chemikalien verwendet werden kann.

6. Einfach zu bedrucken und zu dekorieren: Die Oberfläche der Aluminiumfolie kann für einen hochwertigen Druck beschichtet werden, was ihr ein attraktives Aussehen verleiht.

7. Umweltfreundliches Recycling: Aluminiumfolie ist ein recycelbares Material, das den modernen Anforderungen einer nachhaltigen Entwicklung entspricht.

8. Elektromagnetische Abschirmung: Für elektronische Produkte, die eine antistatische oder elektromagnetische Abschirmung erfordern, kann eine Verpackung aus Aluminiumfolie den notwendigen Schutz bieten.

9. Kosteneffizienz: Im Vergleich zu anderen hochwertigen Verpackungsmaterialien sind Verpackungen aus Aluminiumfolie tendenziell kostengünstiger und können zudem die meisten Verpackungsanforderungen erfüllen.

Der Streifenverpackungsmaschine und Alu-Blisterverpackungsmaschine Der Anwendungsbereich von Aluminiumfolienverpackungen ist sehr breit und umfasst Lebensmittelverpackungen, pharmazeutische Verpackungen, Kosmetikverpackungen, feuchtigkeitsbeständige und antistatische Verpackungen für elektronische Produkte usw. Es ist zu beachten, dass bei der Auswahl von Aluminiumfolienverpackungen auch deren Kompatibilität mit dem Inhalt und die endgültige Entsorgungsmethode berücksichtigt werden müssen, um die Produktsicherheit zu gewährleisten und Umweltanforderungen zu erfüllen.

Nach der Wahl der richtigen Verpackungsmethode, Blisterverpackungsmaschine oder Streifenverpackungsmaschine, Wichtiger ist die Wahl der richtigen Verpackungsmaschine für die Produktion. Wir sind Chinas führender Hersteller von Pharma- und Verpackungsmaschinen. Wir beantworten Anfragen rund um die Uhr online und bieten weltweite Installation, Inbetriebnahme und Schulung vor Ort, schnelle Maschinenlieferung und lebenslange Wartung. Wenn Sie Verpackungsmaschinen kaufen möchten, kontaktieren Sie uns bitte.