Blisterverpackungen dienen als Schutzlösung für Produkte wie Kapseln, Tabletten, Pillen und Süßigkeiten. Sie verfügen über eine transparente, versiegelte Hülle, die eine gute Sichtbarkeit ermöglicht und gleichzeitig die Haltbarkeit verlängert. Die Blisterverpackung wird häufig für Arzneimittel, Elektronik, Lebensmittel und Konsumgüter des täglichen Bedarfs verwendet. Sie erhöht die Sicherheit, verbessert die Präsentation pharmazeutischer Verpackungen und bietet eine dauerhafte, erkennbare Barriere.

Aber was ist eine Blisterpackung? Was ist eine Blisterverpackung? Wo wird Blisterverpackung am häufigsten eingesetzt und welche Faktoren tragen zur weit verbreiteten Akzeptanz bei? Medizin Blisterpackungen? Dieser Artikel untersucht die Anwendungen und Rollen von Blisterverpackungen, ihre verschiedenen Arten, wichtigsten Vorteile und ihre branchenübergreifende Bedeutung in der modernen Pharmaverpackung.

Tabletten-/Kapsel-Blisterpackung, die Tabletten oder Kapseln enthält

Blisterverpackung , durchgeführt von einer Blisterverpackungsmaschine, Bei Blisterverpackungen wird das Produkt in einem Hohlraum fixiert, der typischerweise von einer transparenten Kunststoff- oder Aluminiumfolie umschlossen ist. Die Blisterverpackungen bestehen aus Materialien wie PVC, PET oder Aluminium. Tasche Verpackungen bilden eine Schutzbarriere gegen äußere Einflüsse. Blisterverpackungen werden besonders häufig zum Verpacken von Medikamenten (wie Pillen und Kapseln), Elektronik und Kosmetika verwendet, bei denen sowohl Sichtbarkeit als auch Produktintegrität entscheidend sind.

Beim Blisterverpackungsprozess werden Hohlräume zur Aufnahme von Produkten geformt und anschließend mit einem Deckelmaterial – oft Kunststofffolie, Aluminiumfolie oder einer Kombination – versiegelt. Wichtige Schritte beim Verpacken von Blisterverpackungen sind Formen, Befüllen, Versiegeln und Schneiden. Dadurch wird die Widerstandsfähigkeit gegen Feuchtigkeit, Verunreinigungen und mechanische Beschädigungen gewährleistet und gleichzeitig die Optik der Pharmaverpackung verbessert. Vom Schutz von Pillen und Kapseln bis hin zu manipulationssicheren Gehäusen für Elektronik – Blisterverpackungen sind in zahlreichen Branchen unverzichtbar. Sektoren.

Die Materialauswahl für Blisterverpackungen hängt von branchenspezifischen Anforderungen und der gewünschten Verpackungsart ab. Hier finden Sie die gängigsten Verpackungsmaterialien für Blisterverpackungen und ihre wichtigsten Vorteile.

Hart-PVC ist aufgrund seiner hohen Transparenz und starken Schutzeigenschaften die erste Wahl für Blisterverpackungen. Es schützt Produkte wie Pillen und Kapseln effektiv vor Feuchtigkeit und Verunreinigungen und eignet sich für Pharmazeutika und Konsumgüter. Darüber hinaus ist PVC kostengünstig und daher ideal für die Großserienproduktion, beispielsweise bei der Kapselherstellung, bei der das Budget eine wichtige Rolle spielt. Schlüsselfaktor.

PET ist ein recycelbares Material und bietet eine umweltfreundliche Alternative für Blisterverpackungen. Zwar sind die Barriereeigenschaften nicht mit denen von PVC vergleichbar, doch seine Nachhaltigkeit hat seine Beliebtheit in umweltbewussten Branchen gesteigert. PET sorgt zudem für eine hervorragende Transparenz jeder Blisterverpackung, die für den Einzelhandel unerlässlich ist. Verpackungen, bei denen die Sichtbarkeit die Kaufentscheidungen der Verbraucher beeinflusst.

Für Produkte, die maximalen Schutz benötigen, wie z. B. Medikamente, Aluminiumfolie Der Deckel bietet eine hervorragende Barriere für Blisterpackungen. Er bildet eine sichere Versiegelung gegen Feuchtigkeit, Luft und Licht und ist ideal für empfindliche Produkte wie Pillen und Kapseln, bei denen die Wahrung der Produktintegrität entscheidend ist.

PVDC-Beschichtungen verbessern die Barriereleistung von Kunststofffolien, einschließlich PVC und anderen chlorfreien Alternativen. Diese zusätzliche Schicht aus Erhaltung ist besonders nützlich für Produkte empfindlich Zu Feuchtigkeit und o Oxidation . Bei pharmazeutischen Blisterverpackungen wird häufig PVDC verwendet, um die langfristige Sicherheit der Medikamente zu gewährleisten.

Blase Tasche Verpackungen gibt es auch in verschiedenen Ausführungen, wie z. B. Klappblister, bei denen Blister und Träger zur Wiederverwendung verbunden sind. Diese Art von Blisterverpackung ist in der Elektronik- und Konsumgüterbranche beliebt und bietet sowohl Sicherheit als auch Komfort, während die Produkte sichtbar bleiben.

Neben den Blisterverpackungsmaterialien konzentrieren wir uns nun auf die Blisterverpackung. Bei der Blisterverpackung ist die Formgebung der zentrale Verarbeitungsschritt, der lässt Blasen entstehen. Doch welche verschiedenen Methoden gibt es zur Blasenbildung?

In Die Thermoformen Station einer Blistermaschine Dabei wird eine Kunststofffolie oder -platte erhitzt, bis sie biegsam ist, und dann unter hohem Druck (4–8 bar) in Formhohlräume gepresst, um die Verpackungsform zu erzeugen.

Nach der Formgebung wird der Kunststoff auf eine Temperatur abgekühlt, die sicherstellt, dass er beim Entformen seine Form behält. Bei komplizierten oder größeren Designs sorgt ein „Hilfsstopfen“ für eine gleichmäßige Wandstärke. Diese Methode wird häufig bevorzugt für Pharma-Blisterverpackungen wie Pillen und Kapseln aufgrund seine Geschwindigkeit, Effizienz und Fähigkeit, eine dauerhafte, transparente Schutzschicht zu erzeugen.

Bei der Kaltverformung wird eine Aluminium-Laminatfolie in eine Form gepresst, um eine Blisterkavität zu bilden. Diese Formgebung bietet eine hervorragende Beständigkeit gegen Feuchtigkeit, Sauerstoff und Licht und ist ideal für die Langzeitlagerung von umweltfreundlichen Produkten. empfindliche Produkte wie Pharmazeutika. Kaltgeformte Medizin Blisterpackungen sind undurchsichtig und voluminöser, was die Produktsichtbarkeit und die Effizienz der Blisterverpackung beeinträchtigen kann. Trotzdem bleibt diese Methode für Arzneimitteltabletten und andere Artikel, die einen höheren Umweltschutz erfordern, unverzichtbar.

Thermo-Kaltumformung verschmilzt Vorteile der Kaltumformung Und Thermoformen. Zunächst wird das Produkt mit einer thermogeformten Schicht umhüllt, die eine stabile, durchsichtige Primärbarriere bildet. Anschließend wird eine sekundäre kaltgeformte Schicht hinzugefügt, Verbessert den Schutz der Blisterpackung vor Feuchtigkeit und Sauerstoff. Dieser zweischichtige Ansatz eignet sich ideal für Produkte, die sowohl Sichtbarkeit als auch eine hohe Abschirmung erfordern, und ist daher besonders für umweltempfindliche Güter wie Medikamententabletten oder andere Arzneimittel geeignet.

Nach der Erforschung verschiedener Methoden zur Blasenbildung von der Blisterverpackungsmaschine durchgeführt , ist es auch wichtig, Vorteile zu berücksichtigen, die Blisterverpackung eine bevorzugte Wahl in allen Branchen.

R zuverlässige Blisterpackung Altern Maschine ry , wie Bosch TLT 1400 oder Rich Packing DPP 270Max bietet außergewöhnlichen Schutz für Produkte, insbesondere für solche, die anfällig für Schäden durch Feuchtigkeit, Licht und äußere Verunreinigungen sind. Im Verpackungssektor bilden Blisterverpackungen aus Materialien wie Aluminiumfolie und PVC Schutzschilde, die die Frische der Produkte verlängern.

Blisterverpackungen eignen sich ideal für die Verpackung von Arzneimitteln, kleinen Einzelhandelsartikeln und anderen verderblichen Waren. Die sichere Barriere gewährleistet die Produktintegrität, ohne die Sicherheit oder Leistung zu beeinträchtigen. Damit sind Blisterverpackungen die erste Wahl für Branchen, die Wert auf Qualität legen, insbesondere für unter Einhaltung strenger pharmazeutischer Vorschriften.

Eine Blisterverpackungsmaschine vereint Geschwindigkeit mit Kosteneffizienz. Durch den Verzicht auf zusätzliche Schutzschichten, wie z. B. zusätzliche Plastikfolien oder Kartons, werden die Verpackungskosten deutlich gesenkt. Diese Kostensenkung führt zu wettbewerbsfähigeren Endprodukten auf dem Markt.

In einem anderen Aspekt erleichtert das schlanke, einheitliche Design der Blisterpackungen die mühelose Lagerung und optimiert w Werkstatt Raum und Die Logistik. Darüber hinaus erhöhen anwenderfreundliche Eigenschaften von Blisterverpackungen, wie beispielsweise aufreißbare Nähte oder ein praktisches „Durchdrück“-Design, den Komfort, insbesondere bei Blisterverpackungen für Medikamente.

Ein wesentlicher Vorteil von Blisterverpackungen ist die verbesserte Produktpräsentation. Die klare, transparente Hülle und die anpassbaren Designs ermöglichen den Kunden einen direkten Blick auf die Produkte und steigern so die Marketingwirkung. Blisterverpackungen unterstützen zudem die Markenbildung und Etikettierung. die Funktion erfüllen, anziehend C Kunden ' Aufmerksamkeit in den Regalen. Diese Blisterverpackung ermöglicht Marken, um kostengünstige Lösungen und wichtige Produktvorteile hervorzuheben und den Benutzern den Wert effektiv zu vermitteln.

Angesichts der oben genannten Vorteile ist die Blisterverpackung , geliefert von der Blisterverpackungsmaschine, ist zu einem bevorzugten Lösung für mehrere Branchen, jede mit ihren eigenen spezifischen Anforderungen.

P Arzneimittel-Blisterpackungen , produziert durch eine Blistermaschine in der Pharmaindustrie , Sind weit du tilisiert im Paket Altern Tabletten, Kapseln, Spritzen Und andere Arzneimittel-Blisterverpackungen. P Arzneimittel-Blisterpackungen auch helfen Benutzer S halten Einhaltung ihrer Pläne zur Medikamenteneinnahme . Sicher Und Manipulation- beständig B Lister-Pakete Patientensicherheit gewährleisten y und Rechtliches Industrie Normen, sie machen wichtig für die Gesundheit Institution Das liegt daran, dass sie …

Blisterverpackung zeigt großen Wert in der Lebensmittelindustrie , Erleichterung Snackpaket Altern wie zum Beispiel Schokoriegel, Süßigkeiten , Und Kaugummi. Die Nutzen dieses Pakets ing ist, dass es wirtschaftlich Und genießt hohe Sichtbarkeit von innen Produkte . Ein b Lister Paket ist in der Lage, halten ing Lebensmittel trocken Das verlängern s die Lagerlebensdauer. A ästhetisch ansprechend B Lister-Pakete kann reduzieren Kosten und helfen Produkt S bleiben intakt , Anzug ed für kleine -Größe Produkt Artikel mit hoher Verbraucher Nachfragerotation.

In der Elektronik ist eine Blistermaschine Verpackung in die Anwendung bringen, um Form Muschelschale Hohlräume Das Paket e Gegenstände wie E-Zigaretten und Batterien. Th e Blasenbildung kann helfen Produkte beseitigen, abschütteln körperlicher Schaden und verbessern Sie gleichzeitig die Ästhetik Leistung . B Lister-Pakete von e Elektronik , bieten dem Verbraucher durch ihre transparente Außenseite die Möglichkeit von klar ly Sicht ing das Produkt das wurde verpackt , ermöglicht es Kunden zu geben Kaufentscheidungen ohne Offenlegung Blisterpackungen .

Der Betrieb einer Blisterverpackungsmaschine umfasst mehrere Arbeitsschritte inklusive:

· Heizen & Formen : Kunststofffolie (PVC/PET) wird erhitzt und durch Druck zu Blisterpackungen geformt. Eine optionale PVDC-Beschichtung verbessert die Feuchtigkeitsbeständigkeit.

· Füllen und Verschließen : Produkte (Kapseln, Tabletten, Elektronik usw.) werden in Blister verpackt. Eine Folienabdeckung versiegelt diese und gewährleistet so die Sterilität, insbesondere bei Arzneimitteln.

· Schneiden und Veredeln : Blister werden in einzelne Einheiten oder Blätter geschnitten, mit sauberen Kanten für eine einfache Handhabung. Endgültig Blisterpackungen sind langlebig, schützend und marktreif.

eine automatische Blisterverpackungsmaschine

Die Wahl des richtigen Blistermaschine hängt nicht nur von den Produktspezifikationen, sondern auch von den betrieblichen Anforderungen ab. Nachfolgend finden Sie typische Anwendungsfälle sowie Empfehlungen für geeignete Maschinen für jedes Szenario:

Für Medikamente wie Tabletten, Kapseln und medizinische Instrumente muss eine Blisterverpackungsmaschine eine präzise Befüllung, sichere Versiegelung und strenge Hygiene-Compliance zur Gewährleistung der Patientensicherheit. Wesentliche Merkmale sind:

· Genaue Dosierung und manipulationssichere Versiegelung : Verhindert die falsche Einnahme von Medikamenten und den unbefugten Zugriff.

· Sterile Bedingungen und automatisierter Betrieb : Hält die gesetzlichen Standards ein und eliminiert Kontaminationsrisiken. Die medizinische Blisterverpackung Die Maschine kann den Verpackungsvorgang vollautomatisch und ohne manuelle Eingriffe durchführen.

Empfohlene Ausrüstung:

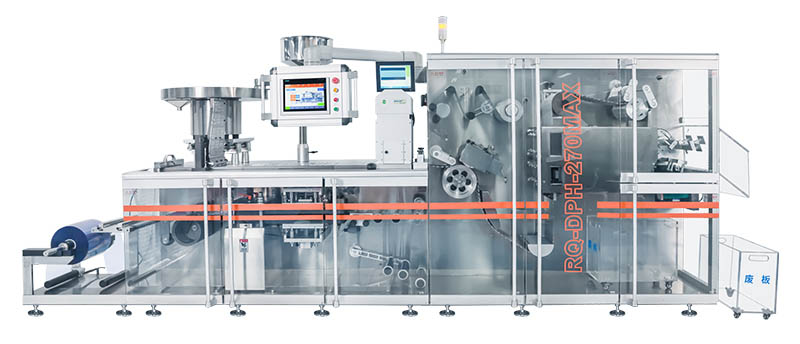

Eine automatisierte, hochpräzise Blisterverpackungsmaschine: Entwickelt für eine schnelle, fehlerfreie Arzneimittelherstellung, die Produktintegrität und -sicherheit gewährleistet. F oder Beispiel, RQ DPP 270Max ist eine vollständig servogesteuerte, hocheffiziente Blistermaschine, die von einem fortschrittlichen SPS-System gesteuert wird. Diese Blisterverpackungsmaschine kann Blister formen, füllen, versiegeln, schneiden, zählen und Automatische Einrückung der Chargennummer, ideal für die pharmazeutische Produktion im großen Maßstab.

RQ DPP 270Max Rollen-Blisterverpackungsmaschine

Artikel wie Batterien, Schaltkreisteile und Befestigungselemente erfordern eine langlebige, diebstahlsichere Verpackung, oft in Form von starren oder Clamshell-Verpackungen. Blisterpackungen .

· Stoßfest und klare Sicht : Schützt den Inhalt und ermöglicht den Kunden gleichzeitig, das Produkt zu prüfen.

· Verbesserte Dichtungshaltbarkeit : Reduziert das Schadensrisiko während des Versands und der Handhabung.

Empfohlene Ausrüstung:

Maschine für starre Blister- oder Heißsiegelverpackungen: Liefert robuste, manipulationssichere Verpackungen mit hervorragender Produktsichtbarkeit.

Bei Verbrauchsgütern wie Schokolade oder Pfefferminz sind schnelle Verpackung und Materialeignung entscheidend.

· Feuchtigkeits- und Sauerstoffbarriere : Verwendet Folie oder Spezialfilme zur Verlängerung Produkt Frische.

· Automatisierter Hochgeschwindigkeitsprozess : Optimiert die Effizienz in der Großserienproduktion und minimiert gleichzeitig die Arbeitskosten.

Empfohlene Ausrüstung:

Die Hochgeschwindigkeits-Blisterverpackungsmaschine: Ideal für die Massenproduktion von Lebensmitteln, anpassbar an verschiedene Konservierungsanforderungen mit verschiedenen Materialoptionen.

Spezialartikel, darunter Kosmetika oder Autoteile, erfordern möglicherweise maßgeschneiderte Verpackungslösungen.

· Vielseitigkeit und Anpassungsfähigkeit : Geeignet für verschiedene Formen, Größen und Materialien.

· Anpassbare Funktionen : Kann einzigartige Designs oder zusätzliche Schutzschichten enthalten.

Empfohlene Ausrüstung:

Mehrzweck Blisterverpackungsmaschine : Bietet Flexibilität für verschiedene Branchen und unterstützt kundenspezifische Formen und Materialien.

Brausetabletten: Vorteile, Verwendung, Gerätehandbuch Welche verschiedenen Pillenarten gibt es?