Tablettenpresse ist ein unverzichtbares Produktionsgerät in der pharmazeutischen Produktion. Auf dem heutigen Markt gibt es jedoch eine große Auswahl an Tablettenpressen, je nach Produkt, Leistung, Budget und anderen Faktoren. Verschiedene Pressentypen weisen erhebliche Unterschiede in Leistung, Anwendungsbereich usw. auf. Die Auswahl der geeigneten Maschine wirkt sich direkt auf die Effizienz der Tablettenproduktion und die Produktqualität aus. Dieser Artikel führt Sie umfassend durch die verschiedenen Arten von Tablettenpressen, ihre Funktionsweise, die wichtigsten Auswahlkriterien und praktische Beispiele, um Ihnen bei der Auswahl der am besten geeigneten Maschine zu helfen.

1. Klassifizierung und Eigenschaften von Tablettenpressen

Funktionsprinzip

Der Rundlauftablettenpresse Die Maschine arbeitet mit mehreren rotierenden Stanzwerkzeugen auf einem Drehtisch, die die Tabletten kontinuierlich verpressen. Durch diese Konstruktion kann die Maschine mehrere Tabletten pro Umdrehung produzieren, was die Produktionseffizienz deutlich steigert.

Hauptkomponenten

- Drehtisch: Unterstützt die Stanzwerkzeuge und ermöglicht eine kontinuierliche Produktion.

- Stanzmatrizen: Verantwortlich für das Füllen, Komprimieren und Formen des Materials.

- Zuführvorrichtung: Kontinuierliche und stabile Zufuhr von pulverförmigen oder körnigen Materialien in den Formhohlraum auf gleichmäßige Weise.

- Kompressionsrollen: Üben Druck auf den oberen Stempel aus, um die Tabletten zu formen.

- Auswurfvorrichtung: Wirft die geformten Tabletten aus der Presse.

Vorteile

- Hohe Produktionseffizienz: Produziert dank mehrerer Arbeitsstationen schnell eine große Menge an Tabletten.

- Hoher Automatisierungsgrad: Die meisten Vorgänge sind automatisiert, wodurch manuelle Eingriffe reduziert werden.

- Präzise Kontrolle des Tablettengewichts: Gewährleistet durch fortschrittliche Kontrollsysteme ein gleichbleibendes Tablettengewicht.

Nachteile

- Komplexe Struktur: Die internen Komponenten sind komplex und erfordern fachmännische Wartung und Bedienung.

- Höhere Wartungskosten: Die komplexe Struktur und die hohe Nutzungsfrequenz führen zu höheren Wartungskosten.

Geeignete Anwendungen

Rotationstablettenpressen eignen sich ideal für die Massenproduktion, beispielsweise in der Arzneimittelherstellung und der Herstellung von Nahrungsergänzungsmitteln im großen Maßstab, wo hohe Effizienz und Automatisierung entscheidend sind.

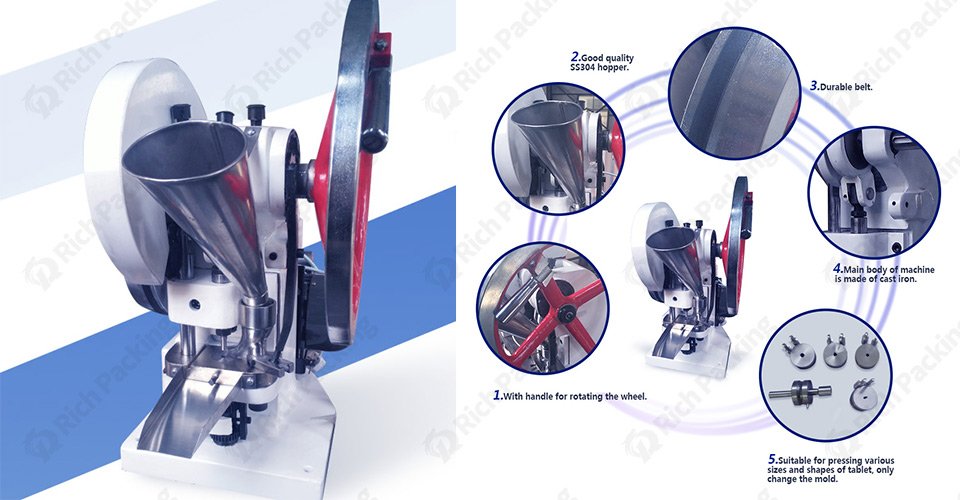

1.2 Tablettenpresse mit Einzelstempel

Funktionsprinzip

Der einzelne Schlag Tablettenpresse Bei dieser Methode wird ein einzelner Satz Stanzmatrizen auf und ab bewegt, um jeweils eine Tablette herzustellen. Im Vergleich zu Rotationspressen ist die Produktionseffizienz bei dieser Methode geringer.

Vorteile

- Einfache Struktur: Das unkomplizierte Design und die Struktur ermöglichen eine einfache Bedienung und Wartung.

- Einfache Bedienung: Geeignet für Produktion und Forschung im kleinen Maßstab, mit minimaler Betriebskomplexität.

- Niedrigere Kosten: Das einfachere Design führt zu niedrigeren Produktionskosten.

Nachteile

- Geringeres Produktionsvolumen: Produziert nur eine Tablette pro Zyklus, was die Produktion im großen Maßstab weniger effizient macht.

- Niedrigerer Automatisierungsgrad: Basiert hauptsächlich auf manueller Bedienung mit eingeschränkten Automatisierungsfunktionen.

Geeignete Anwendungen

Tablettenpressen mit Einzelstempel eignen sich am besten für die Produktion im kleinen Maßstab und für Forschungsumgebungen, in denen hohe Produktionsmengen keine Priorität haben, beispielsweise in der Arzneimittelentwicklung und der Kleinserienfertigung.

1.3 Andere Arten von Tablettenpressen

Hochgeschwindigkeits-Rotationstablettenpresse

Diese Presse wurde für Unternehmen mit extrem hohen Produktionsanforderungen entwickelt und bietet noch höhere Produktionsgeschwindigkeiten, die für die Fertigung sehr großer Mengen geeignet sind.

Mehrschichttablettenpresse

Es handelt sich um eine spezielle Tablettenpressanlage, die Pulver unterschiedlicher Art gleichzeitig zu Mehrschichttabletten pressen kann. Mit dieser Art von Tabletten können Medikamente schichtweise freigesetzt oder zwei oder mehr Medikamente kombiniert werden, um eine bessere therapeutische Wirkung zu erzielen.

Mehrschichttablettenpressen funktionieren nach einem ähnlichen Prinzip wie herkömmliche Tablettenpressen. Dabei wird das Pulver durch Druck zu Tabletten gepresst. Der Unterschied besteht darin, dass eine Mehrschichttablettenpresse über mehrere Trichter und Matrizen verfügt, um mehrere Pulverschichten gleichzeitig einzufüllen und zu pressen.

Tablettenpresse in Sonderform

Diese Presse kann Tabletten in verschiedenen Formen herstellen, erfüllt individuelle Anforderungen und eignet sich für die Herstellung von Spezialtabletten oder Nahrungsergänzungsmitteln.

Um Ihnen den Arbeitsablauf einer Rundlauftablettenpresse besser zu verstehen, veranschaulicht eine HD-Animation den gesamten Vorgang. Diese dynamische Präsentation ermöglicht es Ihnen, die Rolle und das Zusammenspiel der einzelnen Komponenten, einschließlich der Rotation des Drehtellers, der Bewegung der Stanzmatrizen sowie der Materialbefüllungs- und Formprozesse, deutlich zu erkennen.

3. So wählen Sie die richtige Tablettenpresse

Beachten Sie bei der Auswahl einer Tablettenpresse folgende Aspekte:

Produktionsmaßstab

Wählen Sie eine Maschine basierend auf Ihrem jährlichen Produktionsvolumen. Für die Großproduktion eignet sich möglicherweise eine Rundlauf- oder Hochgeschwindigkeits-Rundlauftablettenpresse besser, während für kleinere Betriebe eine Einzelstempeltablettenpresse kostengünstiger sein kann.

Produkteigenschaften

Berücksichtigen Sie die Anforderungen an Härte, Zerfall und Auflösung der Tablette. Verschiedene Pressentypen verarbeiten diese Eigenschaften unterschiedlich. Wählen Sie daher eine Maschine, die Ihren Qualitätsstandards entspricht.

Materialeigenschaften

Verschiedene Materialien stellen unterschiedliche Anforderungen an die Presse, beispielsweise hinsichtlich Klebrigkeit und Fließfähigkeit. Um eine optimale Tablettenqualität zu erzielen, ist es entscheidend, die Eigenschaften Ihres Materials zu kennen und die passende Presse auszuwählen.

Budget

Zwar sind die Anschaffungskosten für hochautomatisierte Geräte möglicherweise höher, doch können sie die Betriebskosten langfristig senken und die Produktionseffizienz verbessern.

Automatisierungsgrad

Berücksichtigen Sie bei der Auswahl der Ausrüstung den Kompromiss zwischen höherer Automatisierung (die zu weniger Arbeitsaufwand und höherer Effizienz führt) und höheren Kosten.

Kundendienst

Prüfen Sie den Kundendienst Ihres Lieferanten, um eine kontinuierliche Wartung und technischen Support für die Geräte sicherzustellen. Die Wahl eines Lieferanten mit einem starken Servicenetzwerk trägt dazu bei, die langfristige Zuverlässigkeit Ihrer Geräte zu gewährleisten.

Hier ist eine Vergleichstabelle verschiedener Arten von Tablettenpressen, die Ihnen dabei hilft, ihre Eigenschaften und Anwendungen visuell zu verstehen:

|

Typ |

Vorteile |

Nachteile |

Geeignete Anwendungen |

|

Rotationstablettenpresse |

Hohe Effizienz, hohe Automatisierung, präzise Gewichtskontrolle |

Komplexer Aufbau, höherer Wartungsaufwand |

Großserienproduktion |

|

Tablettenpresse mit Einzelstempel |

Einfache Struktur, einfache Bedienung, geringere Kosten |

Geringes Produktionsvolumen, geringerer Automatisierungsgrad |

Kleinserienproduktion, Forschung |

|

Hochgeschwindigkeits-Rotations |

Schnellere Produktionsgeschwindigkeit |

Höhere Kosten |

Extrem hohe Produktion |

|

Mehrschichttablettenpresse |

Mehrschichtige Materialkombination |

Geeignet für spezifische Bedürfnisse |

Tabletten für besondere Bedürfnisse |

|

Spezialformpresse |

Produziert verschiedene Formen |

Möglicherweise sind spezielle Formen erforderlich |

Individuelle Tablettenproduktion |

Während des Auswahlprozesses können Ihnen die folgenden häufig gestellten Fragen begegnen:

Wie wählt man die richtigen Stanzmatrizen aus?

Wählen Sie Stanzmatrizen entsprechend der Form und Größe der zu produzierenden Tabletten aus. Stellen Sie sicher, dass die Matrizen Ihren Produktionsanforderungen entsprechen.

Wie löst man Probleme mit dem Festkleben des Tablets?

Probleme mit dem Anhaften von Tabletten hängen oft mit den Materialeigenschaften und den Maschineneinstellungen zusammen. Die Verwendung geeigneter Matrizenbeschichtungen und die Anpassung der Druckeinstellungen können helfen, das Anhaften von Tabletten zu beheben.

Die Auswahl einer Tablettenpresse ist ein komplexer Prozess, bei dem zahlreiche Faktoren berücksichtigt werden müssen. Lassen Sie sich von Experten beraten, besuchen Sie Branchenmessen und prüfen Sie verschiedene Geräte vor Ort, bevor Sie eine Entscheidung treffen. Mit dem technologischen Fortschritt wird sich die Intelligenz von Tablettenpressen weiterentwickeln und der Pharmaindustrie weitere Innovationen bescheren.