Im Juli 2025 brachte Rich Packing, ein führendes chinesisches Unternehmen für pharmazeutische Ausrüstung, offiziell seine neue Generation vollservointelligenter Rundlauftablettenpresse (Modell: RP-HGZP-17). Dieses Gerät wurde für kleine und mittelgroße Pharma- und Gesundheitsproduktunternehmen entwickelt, die empfindlich auf Tablettengewichtsfehler reagieren. Es verfügt über ein Servo-Tablettengewichtskontrollsystem, intelligente Erkennungs- und Aussortierungstechnologie sowie ein modulares, werkzeugloses Formwechselsystem. Es erreicht eine durchschnittliche Tablettengewichtsgenauigkeit von ≤±2 %, verbessert die Formwechseleffizienz um 300 % und unterstützt Kunden bei der Erfüllung von FDA-, UL- und cGMP-Zertifizierungen bei gleichzeitiger Reduzierung des Rohstoffabfalls um 47 %.

♦ Echtzeit-Stanzüberwachung: Verwendet ein Drucksensor-Array am Hauptdruckrad. Effektivität der Rotationstablettenpresse: 99,98 %.

♦ Intelligentes Abfallauswurfsystem: Verwendet Überdruckblasen oder Magnetventilauswurf. Tablettengewichtsqualifikationsrate: >99,99 %.

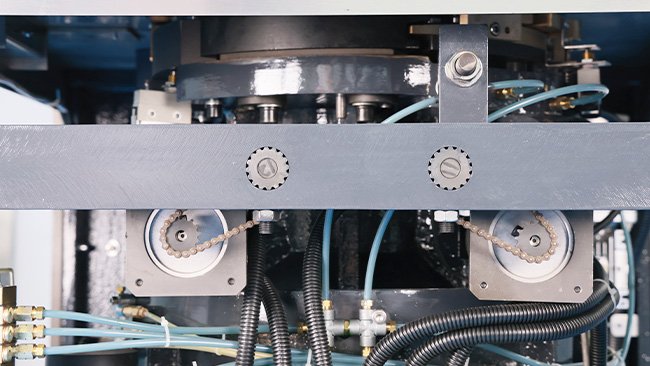

♦ Ultrafeine Bearbeitung der mittleren Matrize: Umfasst eine Bohrmaschine + einen sekundären Bearbeitungsprozess durch Honen. Öffnungstoleranz: ±3 μm.

Unsere intelligente Tablettenpresse verfügt über eine originale Schnellspannvorrichtung für die Mittelmatrize. Diese nutzt eine rechteckige Oberflächenkontaktstruktur für die obere Klemmung der Mittelmatrize und ersetzt die herkömmliche konische Punktkontaktstruktur. Dieses Design reduziert das Risiko, dass sich die Mittelmatrize unter hohem Druck löst, deutlich. Bediener können den gesamten Formwechsel manuell und ohne Werkzeug durchführen und sparen so zwei Stunden Ausfallzeit im Vergleich zu herkömmlichen Geräten.

Der Pulverrückführungsdrehteller im Tablettenkompressor begrenzt die Bewegungsbahn des Restpulvers. Die Pulverrückgewinnungsrate liegt bei >95 %, und die Sauberkeit in der Werkstatt entspricht der Norm ISO 14644 Klasse 7.

Kernkomponenten der Vollservo-Rundlauftablettenpresse nutzen:

♦ Siemens-Servomotoren (Genauigkeit: 0,01°)

♦ ABB-Controller (Reaktionszeit: <2 ms)

♦ SKF-Lager (L10-Lebensdauer: 80.000 Stunden)

16 intelligente Alarmsysteme der Tablettenpresse RP-HGZP-17 decken Szenarien wie Drucküberlastung, Schmierstörungen und Motorüberhitzung ab. Die Presse entspricht der CE/UL-Sicherheitszertifizierung.

Die pharmazeutische Tablettenpresse von Rich Packing unterstützt:

♦ Globale Planung für neue und bestehende Anlagen (Bereitstellung von 3D-Layoutdiagrammen für Produktionslinien).

♦ Installation und Inbetriebnahme vor Ort (unterstützt von unserem globalen Servicecenter in Hongkong).

♦ Umfassende technische Dokumentation (einschließlich vollständiger Benutzerhandbücher, Whitepaper und Videoanleitungen).

Wir sind ein langjähriger Partner von Fortune 500-Unternehmen und Branchenführern in der Pharma- und Gesundheitsproduktbranche, darunter GSK, US-Pharma, Sino-Pharma usw.

Klicken Sie hier, um einen kostenlosen Produktionslinien-Layoutplan zu erhalten → [Jetzt beraten]