1. Einleitung

Gelatine und vegetarische Kapseln sind die häufigsten Materialien für Kapselfüllung in der Pharma- und Nahrungsergänzungsmittelindustrie, die jeweils einzigartige Vorteile bieten. Die Wahl des richtigen Kapseltyps ist entscheidend für den reibungslosen Betrieb Ihrer Kapselfüllmaschine. Dieser Leitfaden untersucht die Unterschiede, Produktionsanforderungen und die Kompatibilität mit Kapselfüllmaschinen , damit Sie eine fundierte Entscheidung treffen können.

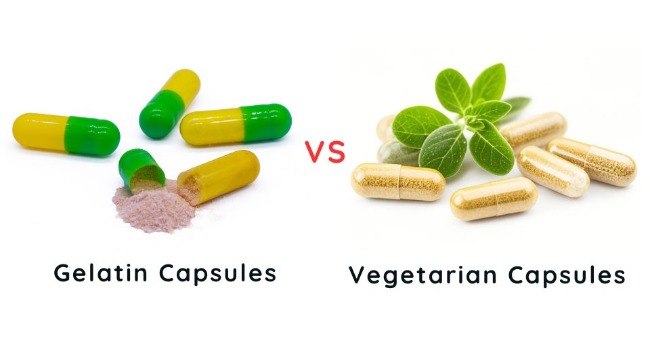

Sowohl Gelatine- als auch vegetarische Kapseln werden häufig in der Kapselproduktion verwendet. Ihre Eigenschaften beeinflussen jedoch ihre Leistung in Kapselfüllmaschinen. Worin besteht also der Unterschied zwischen Gelatinekapseln und vegetarischen Kapseln? Welche Kapseln sind besser mit Kapselfüllanlagen kompatibel? Sehen wir uns die beiden leeren Kapseln genauer an.

Gelatinekapseln werden aus Gelatine hergestellt, einem Protein, das aus tierischem Kollagen, meist von Kühen oder Schweinen, gewonnen wird. Für die Kapselbildung wird es zu einer gelartigen Konsistenz verarbeitet. Aufgrund ihrer glatten Textur und hervorragenden Stabilität werden sie häufig in Kapselfüllmaschinen für Arzneimittel und Nahrungsergänzungsmittel verwendet.

Arten von Gelatinekapseln:

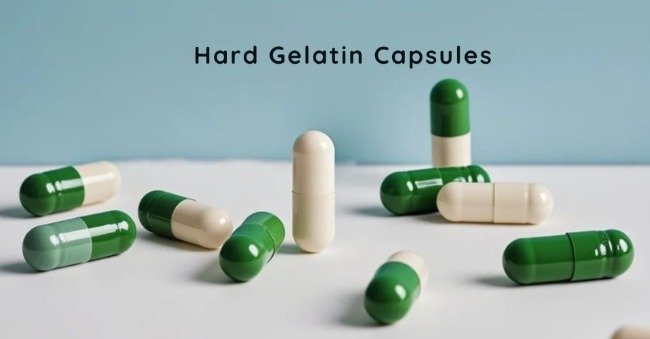

• Hartgelatinekapseln (HGC)

Diese Kapseln bestehen aus zwei Teilen (Körper und Deckel) und werden für Pulver, Granulate und Pellets verwendet. Sie werden häufig für die Anwendung von Vitaminen, Mineralien, pflanzlichen Nahrungsergänzungsmitteln und Formulierungen mit kontrollierter Freisetzung verwendet.

• Weichgelatinekapseln (SGC)

Einteilige hermetisch versiegelte Kapseln aus einem einzigen Stück Gelatine, Softgels sind versiegelt, um Flüssigkeiten oder Öle zu halten, die üblicherweise in Fischöl, CBD-Öl, ätherischen Ölen und flüssigen Medikamenten verwendet werden und spezielle Kapselverkapselungsmaschinen .

Vegetarische Kapseln, hergestellt aus pflanzlichen Substanzen wie Zellulose oder HPMC (Hydroxypropylmethylcellulose), sind eine weit verbreitete Alternative zu herkömmlichen Gelatinekapseln. Mithilfe von Kapselfüllanlagen werden sie häufig in Nahrungsergänzungsmitteln wie Vitaminen, Mineralstoffen und Kräuterprodukten verwendet. Auch für Probiotika und einige pflanzliche Medikamente werden sie häufig eingesetzt.

Hier ist ein kurzer Vergleich zum Verständnis dieser beiden leeren Kapseln.